Key Benefits

HD graphics & vivid color — crisp details and true-to-design tones for premium shelf appeal

Strong ink adhesion — prints bond firmly to PET; resist scuffing and peel-off

Stable & reliable — weather and chemical resistance help maintain color/appearance

Smooth, flat surface — supports clean thermoforming and neat cutting edges

Tough & formable — good tensile/impact for forming, die-cutting and finishing

Food-packaging ready — options for food-contact; documentation on request (e.g., REACH/RoHS)

Typical Applications

Thermoforming blisters & positioning blisters · Chocolate/confectionery & premium food packaging · Sushi trays/boxes · Branded inserts, decorative lids, and display components.

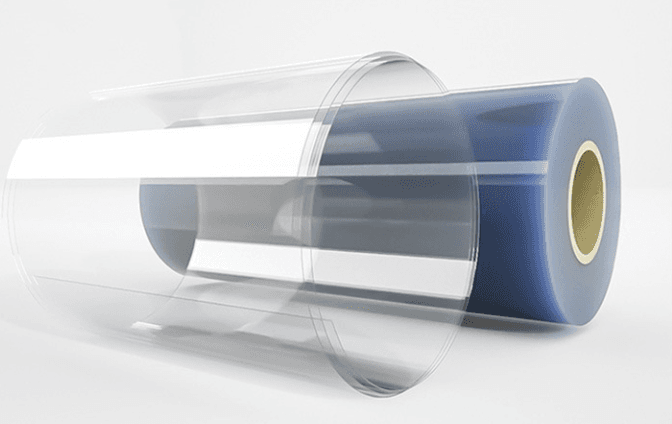

Characteristics of PET printed sheets/rolls:

1. Rich and diverse patterns: It can present various exquisite and complex printed patterns, meeting different design requirements and aesthetic preferences.

2. Vivid colors: It can present bright and realistic color effects.

3. Good adhesion: The printed patterns can firmly adhere to the PET sheet and are not easy to fall off.

4. Strong stability: It has good weather resistance and chemical resistance, and is not easily affected by environmental factors to fade or deteriorate.

5. High surface flatness: It is conducive to the clear display of prints, and the overall appearance is relatively flat and beautiful.

6. Certain strength and toughness: It possesses certain mechanical properties during use.

Specifications

Pattern/Color: Customizable (multi-color, full-coverage or spot)

Thickness: 0.15–2.0 mm

Width: 170–1350 mm

Finish options (on request): gloss or matte, anti-scratch topcoat, print-ready primer/over-print varnish

What You’ll See on the Line

Consistent print adhesion after forming — graphics stay clean and intact

Low scrap and smooth trimming thanks to flat sheet profile

Support available for forming temperature, draw ratio, and ink system selection

7. Good processability: It is convenient for subsequent forming, cutting and other processing operations.