Key Highlights

-

Laminated structures: PET/CPP or PET/PE

-

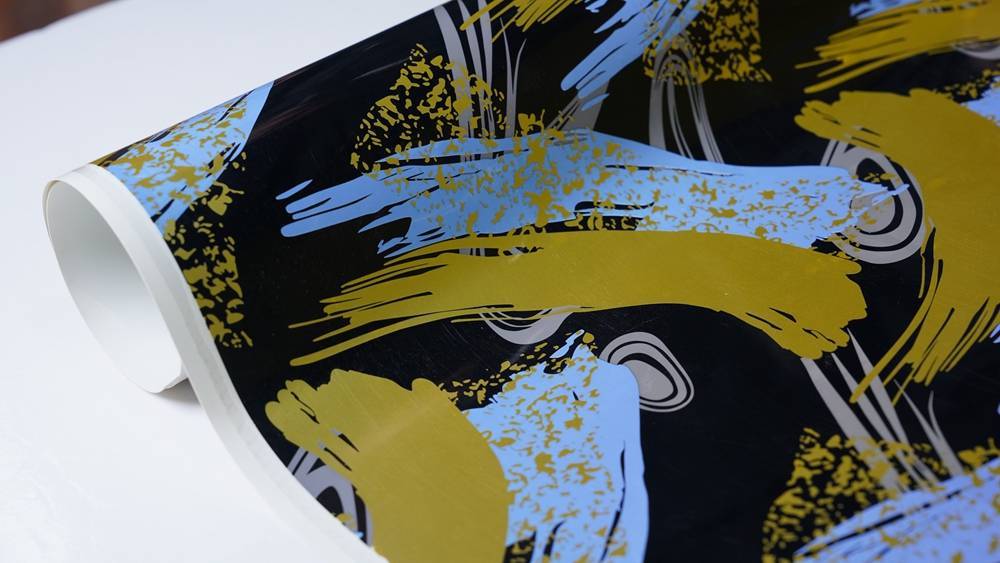

Sharp sushi/Japanese patterns with consistent print quality

-

Stable gauge for multi-cavity thermoforming molds

-

Gloss / matte / anti-scuff options

-

Application-oriented structure recommendation

Product Overview

Sushi packaging is judged at first glance. But the material must also perform during thermoforming and transport.

Our printed laminated sheets are designed to deliver:

-

Clear graphics after forming (pattern stays crisp)

-

Stable production (consistent thickness & roll quality)

-

Better packaging durability (reduced scuffing in stacking & logistics)

Structure Options

PET/CPP laminated sheet roll

A common choice for sushi trays that require improved toughness and stable thermoforming performance.

PET/PE laminated sheet roll

Chosen when a PE layer is preferred for downstream packaging requirements.

Not sure which structure fits your tray line? Share your tray type and forming conditions—we’ll recommend the best laminate.

Key Features

1) Premium print appearance

High-definition sushi/Japanese patterns designed to stay clean and attractive after thermoforming.

2) Laminated performance for real logistics

Lamination adds practical handling benefits for stacking, transport and daily use.

3) Stable gauge & forming consistency

Controlled thickness supports reliable forming and cleaner tray definition.

4) Surface finish options

High gloss for premium shelf appeal, matte for modern look, anti-scuff for tougher logistics.

5) Custom-ready & scalable supply

From sampling to mass production—roll supply designed for continuous lines.

Typical Specifications

Total thickness: 0.15 – 1.20 mm (custom)

Width: 170 – 1350 mm (custom)

Form: roll stock / cut sheets

Structure: PET/CPP, PET/PE

Finish: gloss / matte / anti-scuff (optional)

Custom Pattern & Sampling

Send your artwork (AI/PDF/PSD) or a reference photo. We support:

-

pattern repeat layout for roll printing

-

color matching & sampling plan

-

structure recommendation (PET/CPP vs PET/PE)

For a fast quote, please share:

structure, thickness, width, roll weight, pattern/colors, tray application & forming temperature range.

Applications

-

Thermoforming sushi tray laminated sheet rolls

-

Japanese pattern printed sheets for bento inserts & sashimi trays

-

Chilled takeaway food trays and fresh food packaging

-

Premium display trays and compartment inserts

Features of PET sushi sheets/rolls:

1. Rich and diverse patterns: It can present various exquisite and complex printed patterns, meeting different design requirements and aesthetic preferences.

2. Vivid colors: It can present bright and realistic color effects.

3. Good adhesion: The printed patterns can firmly adhere to the PET sheet and are not easy to fall off.

4. Strong stability: It has good weather resistance and chemical resistance, and is not easily affected by environmental factors to fade or deteriorate.

5. High surface flatness: It is conducive to the clear display of prints, and the overall appearance is relatively flat and beautiful.

6. Certain strength and toughness: It possesses certain mechanical properties during use.

7. Good processability: It is convenient for subsequent forming, cutting and other processing operations.

FAQ

Q1: Which structure is better for sushi trays?

A: PET/CPP is widely used for balanced toughness and thermoforming stability. PET/PE is available when required by downstream needs.

Q2: Can the surface resist scuffing during stacking?

A: Yes—anti-scuff options are available. We can recommend the best surface finish based on your logistics conditions.

Q3: Do you offer custom designs?

A: Yes. Send your pattern file or reference image and we’ll arrange sampling quickly.

CTA

Need sushi pattern printed PET/CPP or PET/PE laminated sheet rolls that run smoothly on your thermoforming line?

Send your tray photo + target thickness/width → we’ll recommend structure and provide samples.