Key Benefits

Low-odor / odorless, no heavy-metal residues, no plate-out/blooming

Excellent heat stability, light stability and long-term color hold

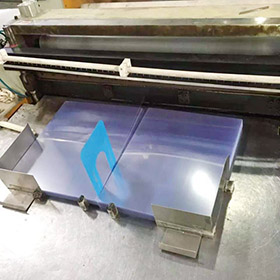

Supports rigid calendering, sheet/film extrusion and blown film

RoHS-compliant (documentation available on request)

Proven in production and helps reduce overall processing cost

Typical Applications

Rigid PVC calendered sheet & film, profile/pipe extrusion, blown film.

Typical Applications

Rigid PVC calendered sheet & film, profile/pipe extrusion, blown film.

Recommended Use

Start at supplier-recommended phr for rigid PVC (e.g., 0.8–1.5 phr as a typical range; finalize on line). Fine-tune internal/external lubrication to maintain a flat torque curve and clean die lips.

Compliance & Documents

RoHS statement and lab reports available upon request.

Customer usage site:

Powder Calcium-Zinc (Ca-Zn) PVC Stabilizer

Lead-free performance for modern PVC processing.

Our powder Calcium-Zinc (Ca-Zn) stabilizers deliver thermal stability and clean processing without the heavy metals found in legacy systems. Formulated with sustainability in mind, they support high output, consistent color, and durable end-use properties across a wide range of PVC applications.

Why Choose Ca-Zn Stabilizers

Heavy-metal free: No lead, cadmium, barium, or organotin.

Compliance ready: Formulations available to support REACH and RoHS documentation.

Strong thermal stability: Maintains integrity under elevated processing temperatures.

Smooth processing: Balanced lubricity and dispersion for stable torque, clean die lips, and fewer changeovers.

Reinforced properties: Excellent coupling action that improves weld strength and overall mechanical performance.

Typical Applications

Wires & cables – reliable insulation and long service life.

Window & technical profiles – including foamed profiles with stable color and surface quality.

Pipes & fittings – soil and sewer pipes, foam-core pipes, land drainage, pressure pipes, corrugated pipes, and cable ducting, plus matching fittings.

What You Can Expect in Production

Fast start-ups with stable torque and minimal plate-out.

Consistent whiteness and gloss retention where required.

Good flow and dispersion in both extrusion and calendering.

Support for food-contact or low-odor targets (on request, depending on grade).

Documentation & Support

Compliance statements (e.g., RoHS/REACH) and lab data are available on request. Our technical team can recommend the right Ca-Zn grade and optimize phr & lubrication balance for your line.

Call to action: Send your resin and process details—get a matched Ca-Zn formula and samples within 48 hours.