Why PS from Us

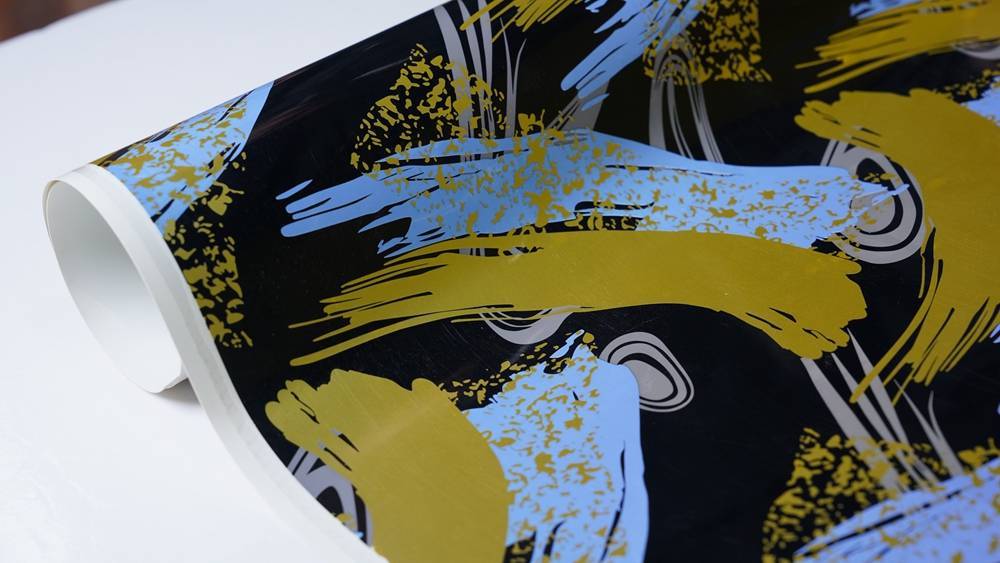

Clear & glossy for premium display; optional matte/colored finishes

Forming stability with tight thickness control → fewer adjustments, low scrap

Food-contact oriented; documentation available on request (e.g., REACH/RoHS)

Customizable: color/pattern, 0.15–2.0 mm thickness, 170–1350 mm width

Easy-peel lidding & rigid carriers for frozen treats.

Benefits: controlled peel force, no residue; stable under chill conditions; moisture barrier for freshness; abrasion-resistant surface

Applications: ice-cream/dairy bars, frozen desserts, yogurt sticks

Specs: clear/colored or printed · 0.15–2.0 mm · 170–1350 mm

Application:

Vacuum forming and positioning vacuum forming, cheese sticks and other dairy product packaging.

Features of PS cheese stick packaging sheets/rolls:

1. Easy to peel: It is convenient to open, has good initial adhesion and controllable peel force, allowing the film to be easily and cleanly separated from the substrate without leaving any residue.

2. Strong stability: It maintains stable physical properties under different environments (such as temperature changes and humidity changes), and is not prone to deformation or damage.

3. High barrier performance: It has excellent barrier capabilities against gases (such as oxygen and carbon dioxide) and moisture, effectively extending the shelf life of products.

4. Durability: It features excellent mechanical strength and wear resistance, capable of protecting the contents from damage during transportation and storage.

5. Aesthetic display: It features excellent transparency and smoothness, providing a good display effect.

6. Safe edible grade: It can be used for packaging fresh dairy products.

What You’ll See on the Line

Fast start-ups with stable forming window

Neat cutting edges and consistent rim strength

Lower rework due to flat sheet profile and uniform gauge

Call to Action

Get Samples in 48h · Request Forming & Peel Specs · Get a Tailored Grade