What Is Lamination—and Why It Matters

Lamination bonds a transparent plastic film to a substrate under heat/pressure to protect the surface and enhance gloss. Proper lamination improves water and oil resistance, durability, and shelf appeal—key for thermoformed trays, lidding, labels, and medical seals.

Why PE Is the Go-To Inner (Seal) Layer

Polyethylene (PE) is colorless, odorless, non-toxic, and semi-transparent. It combines mechanical strength, dielectric properties, and moisture resistance (even in high humidity). PE maintains flexibility and chemical stability down to about −70 °C, which is why it’s favored for cold-chain packaging and peelable seals. Typical grades include LDPE, MDPE, and HDPE—selection depends on process and end-use.

Common Laminate Stacks—And When to Use Them

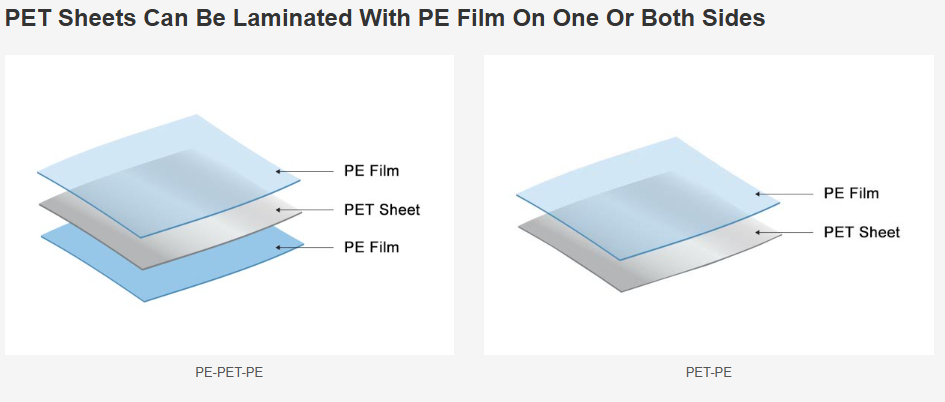

PET/PE (Polyester + Polyethylene)

- Why: PET brings optics, stiffness, and printability; PE adds sealability and moisture protection.

- Use cases: Food lidding, thermoformed trays, labels, cosmetics, medical peel seals (with the right grade and compliance).

Caption: PET/PE for high-clarity lidding and formable trays; seal window tuned via PE grade.

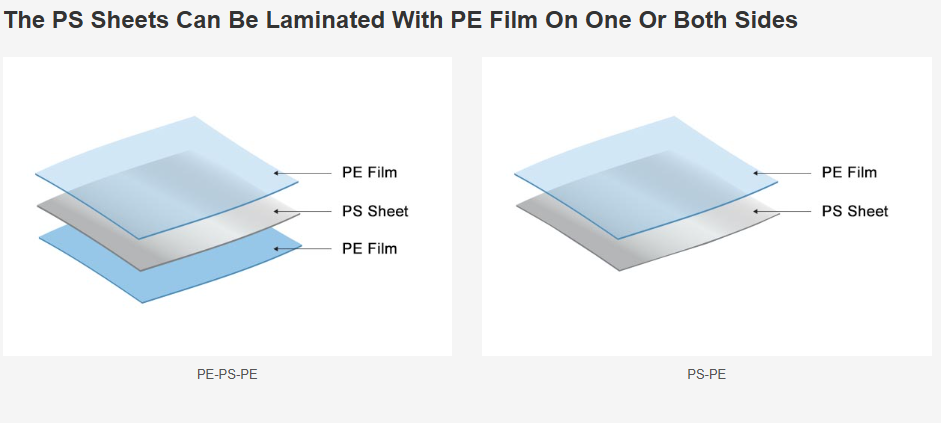

PS/PE (Polystyrene + Polyethylene)

- Why: PS is an ideal thermoforming substrate; PE contributes barrier to air, moisture, oil and certain chemicals.

- Use cases: Dairy cups, confectionery/snack trays, medical blister bases—when forming efficiency + seal are key.

Caption: PS forms cleanly; PE adds seal and barrier—popular in dairy/snack packaging.

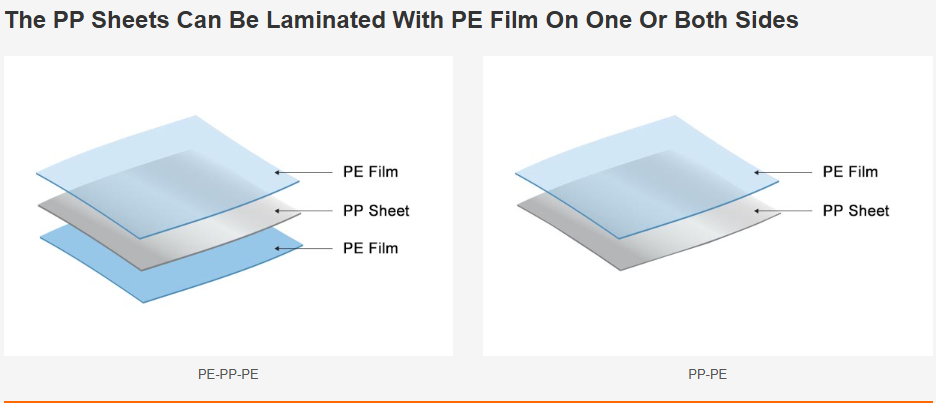

PP/PE (Polypropylene + Polyethylene)

- Why: PP improves toughness and heat tolerance; PE ensures a broad sealing window and moisture barrier.

- Use cases: Hot-fill or microwave-tolerant lidding, industrial trays needing chemical resistance.

Caption: PP/PE is common for higher-temp lidding and tougher trays.

Quick Selection Guide

|

Scenario |

Recommended Stack |

Why It Works |

|

Food lidding (cold/ambient) |

PET/PE |

PET optics + printability; PE sealing & moisture barrier |

|

Snack/dairy trays (thermoforming) |

PS/PE |

PS forms fast/clean; PE adds seal & barrier |

|

Hot-fill/microwave tolerant |

PP/PE |

PP heat resistance; PE sealing window |

- Thickness & width: Define total gauge/tolerance. Typical sheet ranges 0.15–2.0 mm, widths ~170–1350 mm (line-dependent).

- Barrier targets: Match OTR/WVTR to shelf-life; consider coated/metallized PET for higher oxygen/moisture barrier.

- Seal window: For lidding, specify jaw type, temperature, dwell, pressure and target peel force if easy-peel is required.

- Thermoforming: Lock heating profile and draw ratio; confirm tooling radii to prevent thinning and stress whitening.

- Compliance: Request food-contact declarations; for medical, verify sterilization compatibility and migration data.

Caption: A clear spec table speeds qualification and reduces trial-and-error on the line.

Typical Applications

- Food packaging: thermoformed trays, easy-peel lidding, VSP (skin-pack), snacks & dairy

- Medical & hygiene: blister bases, peelable seals (with appropriate compliance)

- Consumer & electronics: printed cards, carton windows, protective over-lamination

- Industrial: impact-resistant trays, component organizers, moisture/dust covers

FAQs

Q: When should I choose PET/PE over PS/PE?

A: Choose PET/PE for clarity/print quality in lidding or display; choose PS/PE for thermoforming efficiency and cost-effectiveness in trays.

Q: Can I design for peelability?

A: Yes. Pair the right PE seal layer with surface treatments/coatings and dial jaw temp/dwell/pressure to hit a target peel force. We can help map the seal window.

Q: Are these laminates suitable for chilled or frozen chains?

A: With the correct PE grade/structure, laminates remain flexible at low temperatures and maintain moisture resistance, making them suitable for chilled/frozen logistics.

Q: Do you supply sheets and rolls?

A: Yes—sheets or rolls for PET/PE, PS/PE, PP/PE, and PVC/PE are available depending on your process.

Call to Action

Need a matched formulation or sample rolls? Explore PET easy-peel sheets and high-barrier PET (OTR/WVTR), or contact us for a 48-hour sample pack.