Supermarket Meat, Seafood & Sushi Trays: How to Choose Thermoforming Sheets for Barrier, Anti-Fog, Easy-Peel & Printing

-

For chilled supermarket trays, the “real spec” is not only PET vs PP—buyers typically need a performance package: barrier + anti-fog clarity + easy-peel opening + stable sealing.

-

Laminated sheet rolls (PET/CPP, PP/CPP, PET/PE) are often the most practical way to achieve consistent shelf performance and a wider processing window.

-

If you want higher shelf impact, sushi printed trays and gold metallized looks can be scaled reliably when printing/lamination and forming requirements are defined clearly.

-

Use the one-page RFQ checklist at the end to get the right structure faster and avoid repeated sampling.

1) Why “function + appearance” now drives supermarket tray packaging

Walk past any supermarket chilled cabinet: fresh meat, salmon, shrimp, sushi sets—what sells is often decided in seconds. The packaging must support four critical outcomes:

-

Clear display (anti-fog): Temperature swings in chilled cabinets create condensation and fogging, reducing visibility of color and texture—often a direct hit to conversion.

-

Stable freshness (barrier): Protein products can be sensitive to oxygen and moisture. When distribution and display cycles get longer, barrier requirements become more important.

-

Good opening experience (easy-peel): Consumers want clean, easy opening—while logistics still require secure sealing.

-

Shelf impact (printing / premium looks): Sushi patterns, branded graphics, and premium metallic looks are increasingly common for differentiation.

That’s why many projects shift from “Can you supply a sheet?” to “Can you deliver a complete performance spec consistently?”

2) Different protein applications = different priorities

Start by mapping the product to its dominant risk:

A. Fresh meat & poultry trays (chilled)

-

Priorities: color display, reduced fogging, consistent sealing

-

Common needs: anti-fog, stable seal window, toughness for cold-chain handling

B. Seafood & fish trays

-

Priorities: moisture/odor management, cold resistance, seal stability

-

Common needs: better processing window, cold toughness, and barrier upgrades when required

C. Sushi & ready-to-eat trays

-

Priorities: visual identity + clean opening

-

Common needs: sushi printed sheets/rolls, easy-peel, and anti-fog for chilled display

3) Barrier basics (OTR/WVTR) for thermoformed trays—what to define

OTR and WVTR matter most when you translate them into real project decisions:

-

Are you controlling oxygen exposure, moisture transfer, or both?

-

Are you evaluating barrier on the flat sheet, or on the formed tray? (Deep forming can thin corners and change performance.)

Practical tip: Define barrier in tiers—Standard / Enhanced / High barrier—based on shelf-life and distribution reality. This keeps you from over-specifying and inflating cost unnecessarily.

4) Anti-fog: a high-ROI feature that’s often underestimated

Fogging is not just a “visual issue.” It can directly reduce sales because customers can’t clearly see the product.

When anti-fog is strongly recommended:

-

chilled display > 24–48 hours

-

products where appearance drives purchase (fresh meat, salmon, sashimi, sushi sets)

-

you want fewer complaints about “cloudy” packs

Anti-fog is usually delivered via a matched lidding solution and surface performance design—so it should be included early in the spec, not treated as an afterthought.

5) Easy-peel: don’t just say “easy to open”—spec it

Most easy-peel problems come from unclear requirements:

-

too hard to open (peel force too high)

-

tearing/stringing (messy peel)

-

premature opening during transport (peel force too low or unstable sealing)

A good RFQ specifies:

-

target seal window (temperature range)

-

target peel force (or “consumer easy-open”)

-

desired peel mode: clean peel / no stringing / no tearing / no residue

-

sealing equipment conditions (sealer type, dwell time, pressure)

6) Why laminated sheet rolls are often the best fit for supermarket trays

If you need barrier + anti-fog compatibility + easy-peel + high-quality printing, laminated structures typically deliver more consistent results.

Here’s a buyer-friendly way to describe your options:

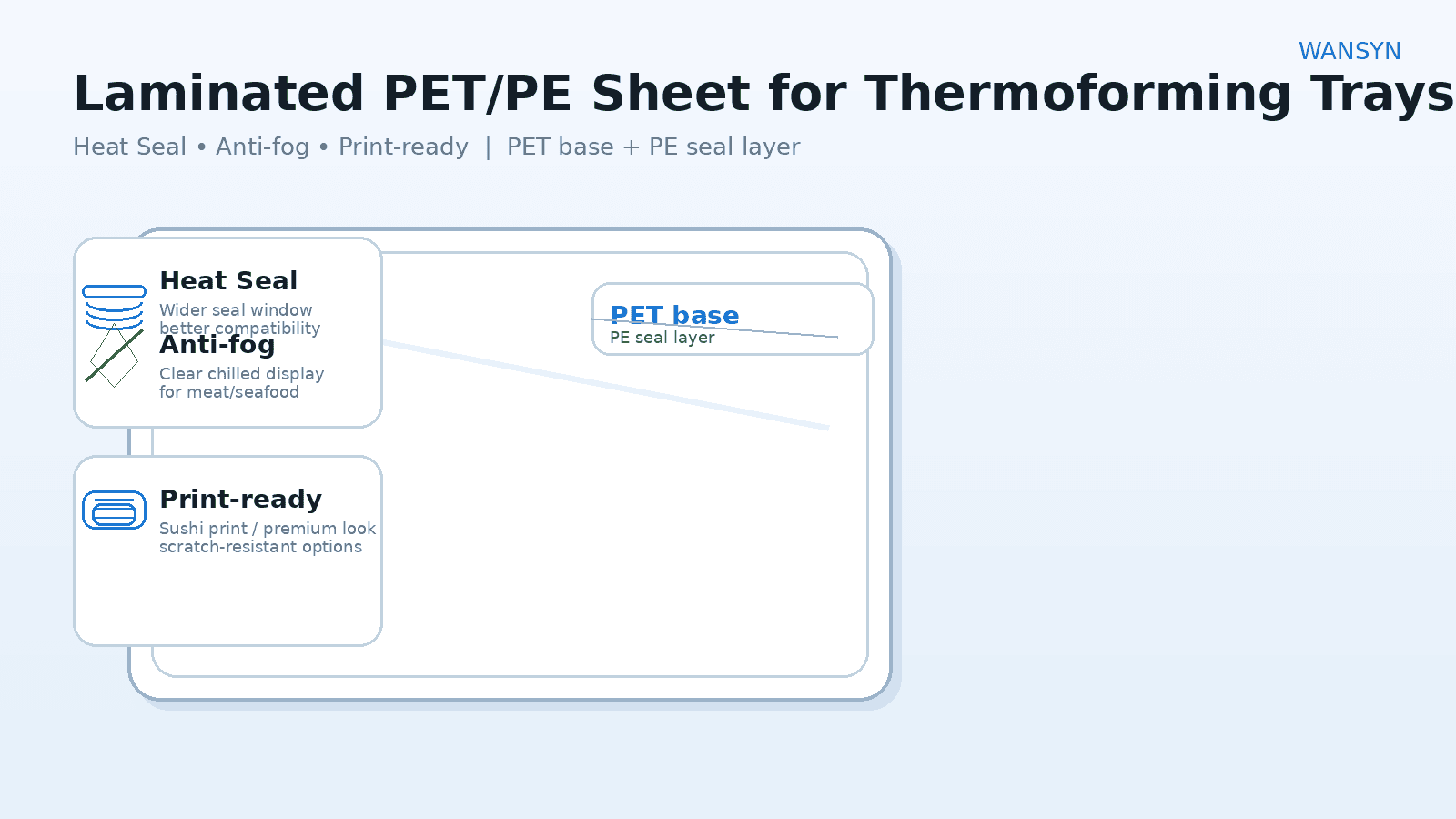

PET/CPP laminated sheet rolls

-

Best for: balanced performance (clarity + forming stability + surface/seal layer matching)

-

Typical uses: sushi trays, chilled display trays, printed packaging formats

-

Strength: wider processing window and reliable converting performance

PP/CPP laminated sheet rolls

-

Best for: PP-based systems where toughness and process stability are priorities

-

Compatible with: anti-fog and easy-peel solutions depending on the overall system

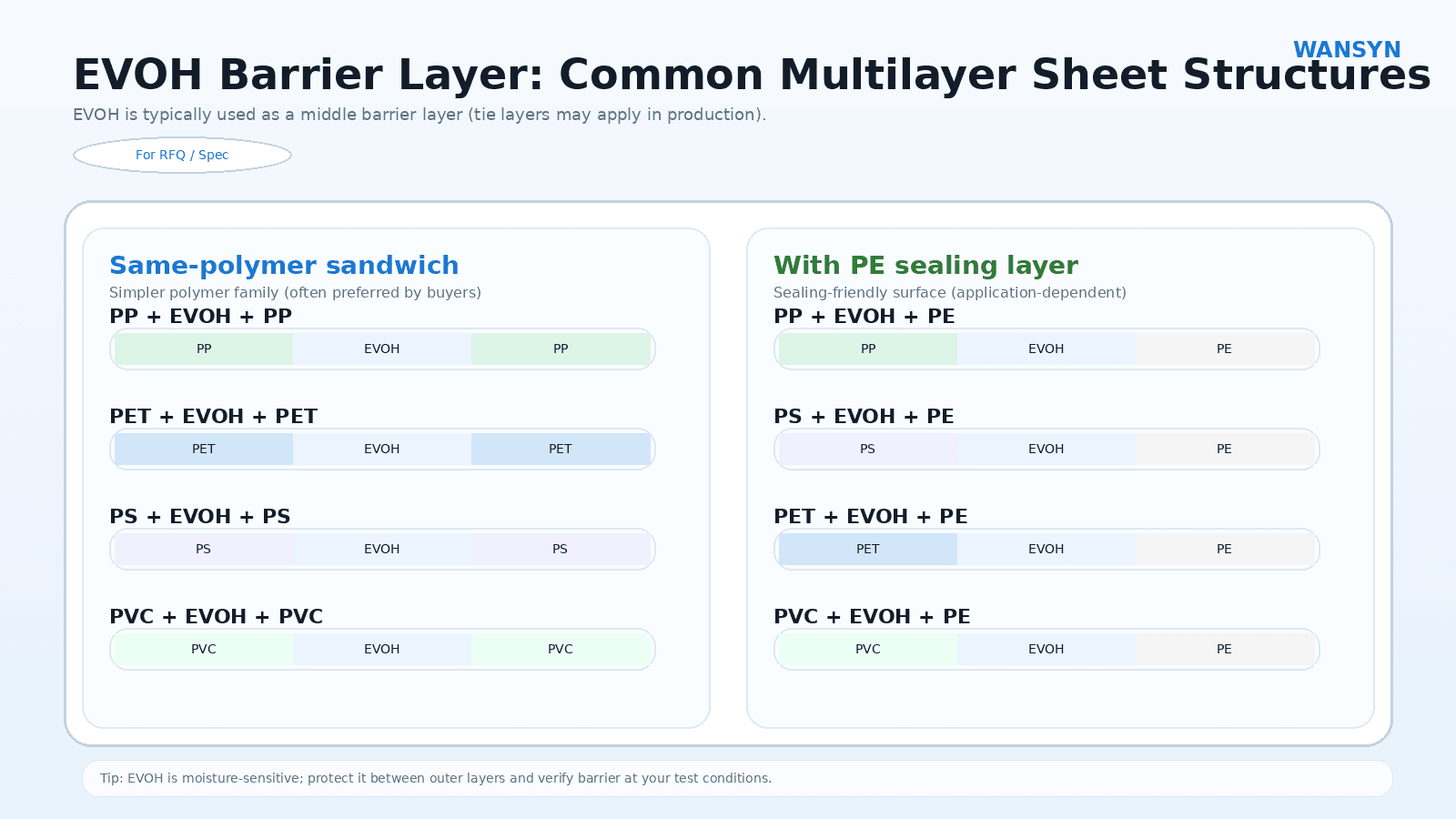

PET/PE laminated sheet rolls

-

Best for: specific sealing systems and cost-performance balancing

-

Note: End-of-life preferences vary by market—confirm recyclability expectations early to avoid redesign later.

7) Shelf differentiation: Sushi printed trays & gold metallized looks (done for production)

Sushi printed trays (printed sheet/roll)

For stable, scalable results, many high-volume programs prefer printing + lamination, because the print layer is better protected and more durable.

Include these in your RFQ:

-

artwork area and color requirements

-

scratch resistance / rub resistance

-

roll or sheet format preference

-

forming depth and tooling notes

Gold metallized PET (premium inserts & festive packaging)

Gold metallized looks are popular for chocolate inserts, gift trays, seasonal and premium food packaging. The key is aligning the visual requirement with forming behavior and protection layers.

8) One-page RFQ checklist

Send this to your supplier to speed up structure recommendation and sampling:

-

Product: meat / seafood / sushi tray (details: ______)

-

Preferred structure: PET/CPP / PP/CPP / PET/PE (or “please recommend”)

-

Thickness: ___ mm (range ok: ___)

-

Width / Roll OD / Core: ___ / ___ / ___

-

Forming depth: ___ mm; vacuum/pressure; line speed: ___

-

Appearance: high clarity / matte / sushi print / gold metallized

-

Barrier targets: OTR ___; WVTR ___; test basis: flat sheet / formed tray

-

Anti-fog: yes/no (chilled display: ___ days)

-

Easy-peel: seal window ___°C; peel target ___ (or “consumer easy-open”)

-

Cold resistance: chilled/frozen temp ___°C; handling/drop requirement: ___

-

Compliance: food-contact requirements for your market: ___

FAQ

Q1: Do meat and seafood trays always need high barrier?

Not always. Start from shelf-life and distribution needs, then define barrier tiers to avoid over-specifying.

Q2: Is anti-fog really worth it for supermarkets?

If your product sits in chilled display and visibility drives sales, anti-fog can be a strong ROI feature.

Q3: How do I specify easy-peel correctly?

Seal window + peel force target + desired peel mode (clean peel/no stringing) + your sealing conditions.

Q4: Should I source printed trays as sheets or rolls?

Rolls are often better for high-volume consistency and print/lamination workflows; sheets can fit certain converting setups.

If you are developing supermarket trays for fresh meat, seafood, or sushi, we can recommend a suitable laminated structure (PET/CPP, PP/CPP, PET/PE…) based on your forming depth, chilled display time, sealing method, and barrier targets—and support with samples and application guidance.