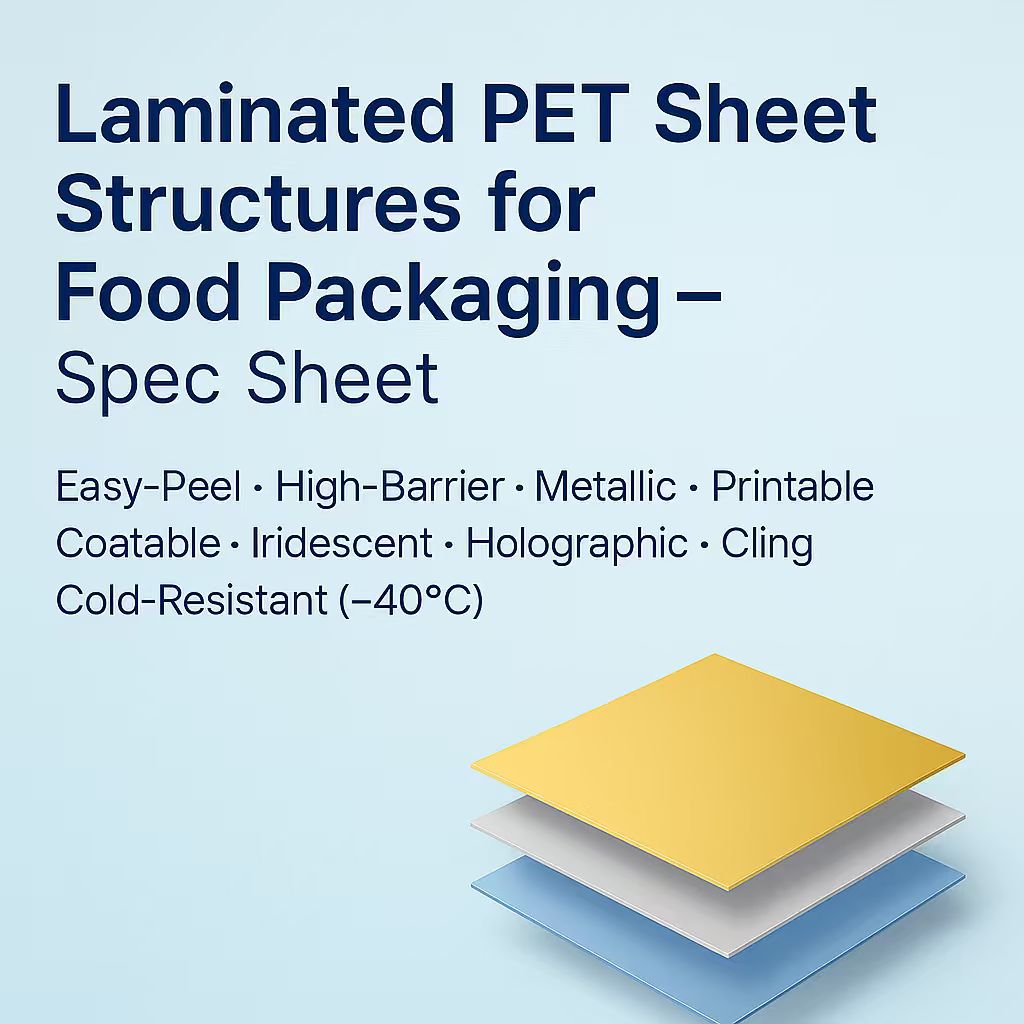

Laminated PET Sheet Roll – Functional Multi-Layer Solutions for Modern Packaging

Easy-Peel · High-Barrier · Metallic · Printable · Coatable · Iridescent · Holographic · Cling · Cold-Resistant (–40°C)

WANSYN Industry supplies laminated PET sheet rolls that combine a high-performance PET substrate with one or more functional layers, creating a versatile material for food packaging, thermoformed trays, lidding, electronics and medical packs.

By leveraging the mechanical strength of PET and the special functions of laminated films, our solutions help converters and brand owners upgrade both pack performance and shelf appearance without changing existing thermoforming or sealing lines.

What Is a Laminated PET Sheet Roll?

A laminated PET sheet roll consists of:

PET substrate layer – rigid, clear, with good mechanical strength and heat resistance.

Functional film layer(s) – to add barrier, printability, metallic effect, anti-fog, cling, etc.

Adhesive layer – to bond the structure and ensure long-term stability.

This multi-layer design allows you to keep the excellent base properties of PET while tuning surface and barrier performance for different applications.

Specification

Laminated PET sheet roll is a material composed of PET substrate and one or more layers of functional film.

· Thickness: 0.15-2.0mm

· Width: 170-1350mm

· Color: Transparent or Customized

Special performance customization: easy-peel, high-barrier, metallic, printable, coatable, iridescent, holographic, cling and cold-resistant cling (down to –40 °C).

· Delivery time: 7~15 days since receipt of PO and down payment.

· Payment Accepted: D/A, D/P, T/T, L/C, Westunion etc.

· Samples: Free samples supply

Brif Intro

Laminated PET sheet roll is a material composed of PET substrate and one or more layers of functional film. It has the excellent mechanical properties of PET substrate and the special functions of functional film, making it a composite material with excellent performance and wide application.

PET substrate has good transparency, chemical resistance and heat resistance, and the laminating material can enhance the surface properties of PET substrate, making it more wear-resistant, scratch-resistant, anti-static, etc. Laminated PET sheet roll is widely used in food, beverage, medicine, electronics and other industries.

PET sheet roll parameters

|

Product name |

PET sheet roll, Food grade PET sheet, PET thermoformed blister sheet |

|

Product Category |

PET/CPP,PET/PE, etc. |

|

Shape |

Roll/Sheet |

|

Thickness |

0.15~2.0mm |

|

Width |

170~1350mm |

|

Quality |

Virgin/Recycled |

|

PET Roll Diameter |

≤700mm |

|

Die Cutting Size |

A2, A3, A4 or customized according to requirements |

|

Packing |

PE film inside + pallet (paper tube diameter: 76mm, thickness: 10mm) |

|

Color |

Clear, White, Blue, Brown, Pink, Green, Yellow or Customized |

|

Performance |

easy-peel, high-barrier, metallic, printable, coatable, iridescent, holographic, cling and cold-resistant cling (down to –40 °C). etc. |

|

Processing technology |

Thermoforming Vacuum Blister Forming, Die Cutting |

|

Hardness |

Rigid/Semi-rigid |

WANSYN Laminated PET Functional Series

PET sheet type we offer

|

PET sheet type |

Width (mm) |

Thickness (mm) |

|

Easy-Peel PET Lidding Film & Thermoforming Sheet |

300-1400 |

0.18-2.0 |

|

High-Barrier PET Packaging Sheet & Roll |

||

|

Metallic & Gold-Metallized PET Thermoforming Sheet/Roll |

||

|

Printable PET Sheet & Roll for High-Definition Graphics |

||

|

Iridescent (Rainbow) PET Decorative Sheet & Roll |

||

|

Holographic PET Film & Thermoforming Sheet |

||

|

Cling-Type PET Stretch & Wrapping Film |

||

|

Cold-Resistant Cling PET Film & Sheet (-40°C) for Frozen Food Packaging |

Based on one core PET platform, we offer multiple functional series to meet different packaging needs:

Easy-Peel Laminated PET Sheet & Lidding Film

For ready meals, dairy cups, dessert cups and salad trays.

Controlled peel strength, compatible with common tray materials (to be matched per project).

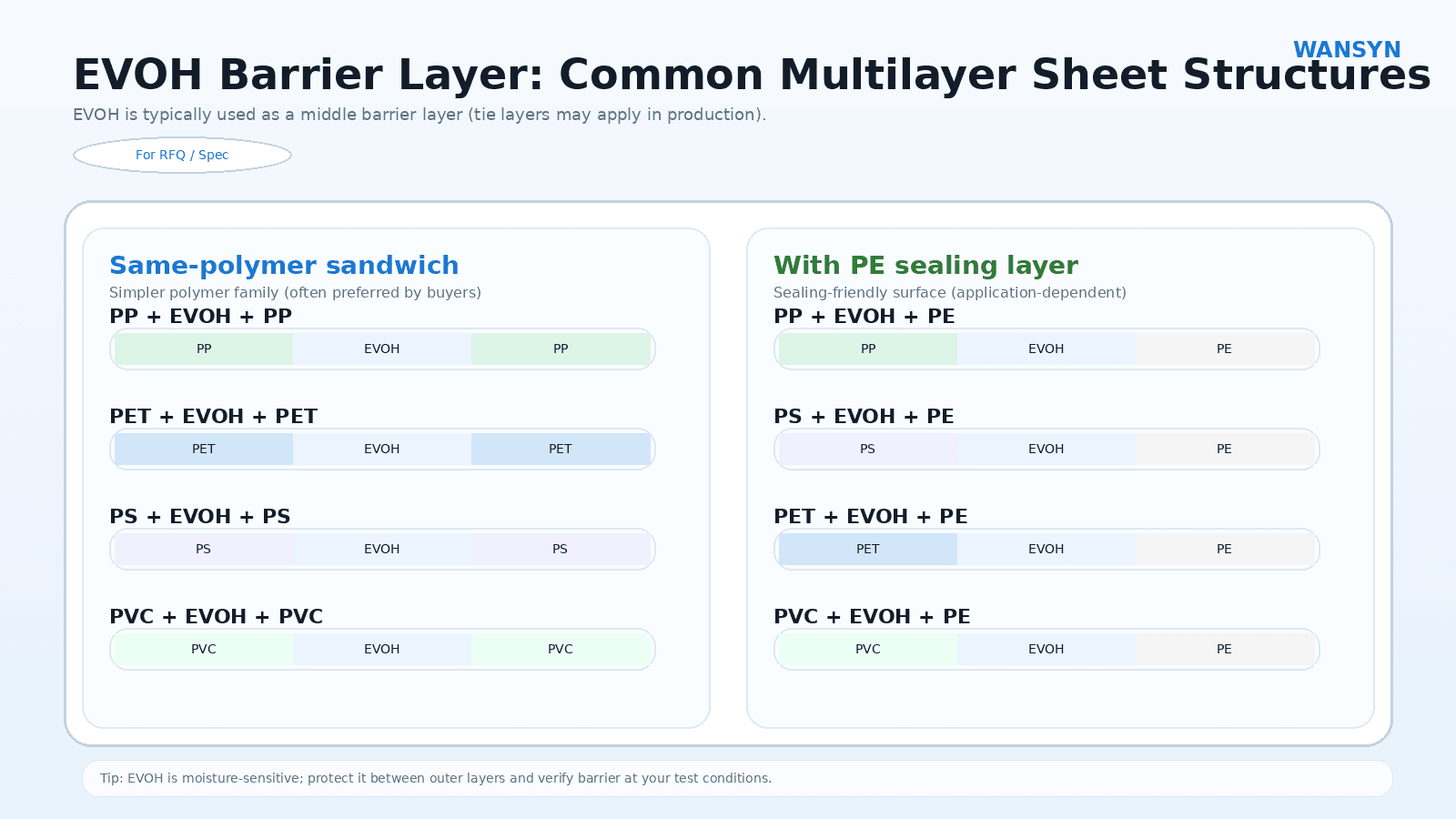

High-Barrier Laminated PET Sheet & Roll

PET/EVOH and other barrier structures for meat, cheese, seafood and high-value foods.

Designed for MAP trays, high-barrier lids and extended shelf life packaging.

Metallic & Gold-Metallized PET Laminated Sheet

Metallic gold / silver / champagne / coffee-gold finishes for chocolate trays, mooncake and luxury gift box inserts.

High gloss or matte options, shade can be matched to your sample.

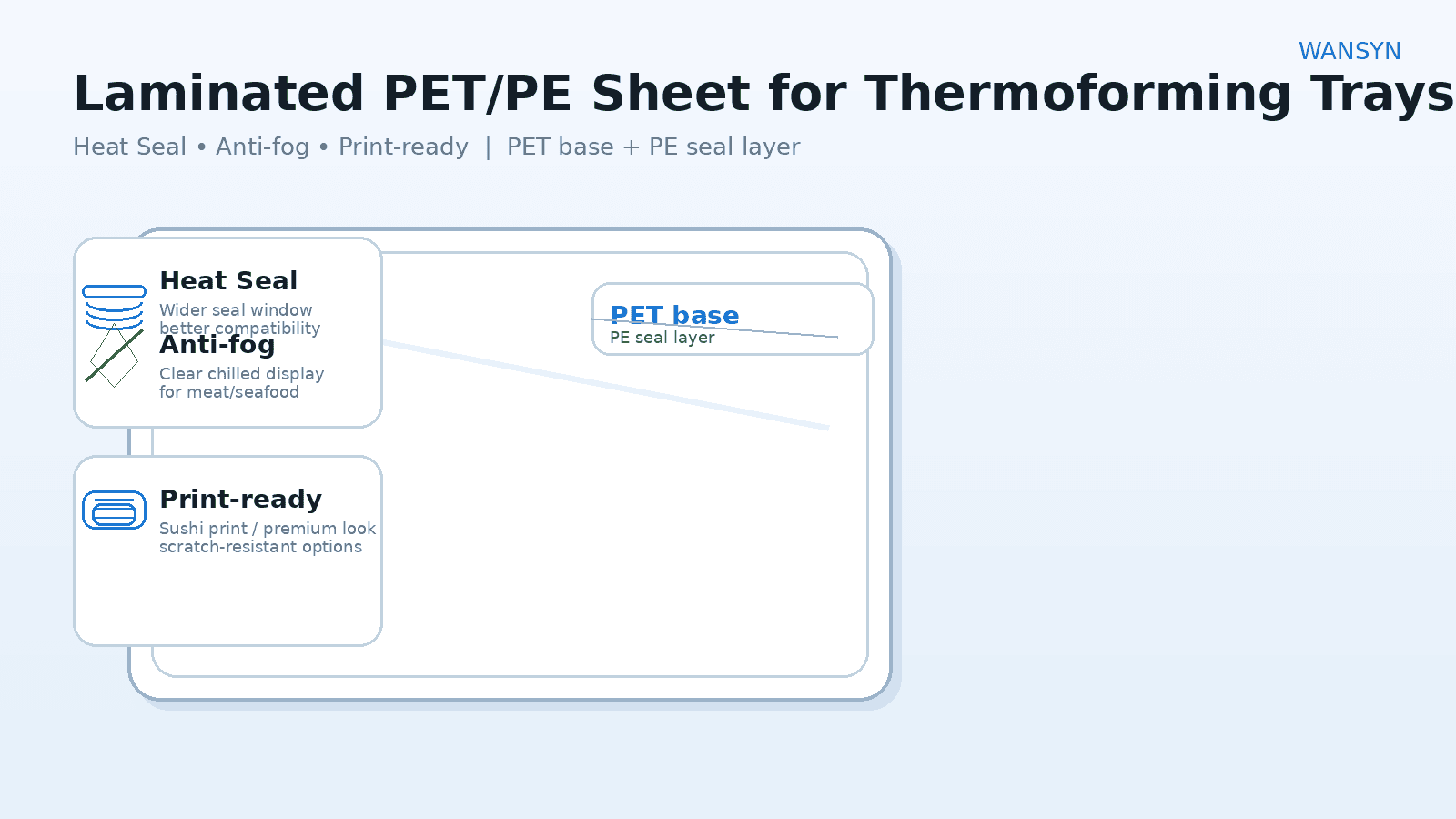

Printable & Coating-Grade Laminated PET

Surface-optimized for high-definition printing or downstream coating.

For printed lids, branded thermoformed trays, labels and graphic applications.

Iridescent (Rainbow) Laminated PET Sheet & Roll

Color-shift, rainbow effect for gift packaging, cosmetics and festive promotions.

Holographic Laminated PET Sheet & Film

Diffraction patterns (dots, lines, logos, custom patterns) for premium and semi-security packaging.

Controlled cling for surface protection, bundling and light wrapping, with low residue.

Cold-Resistant Cling PET Sheet & Film (Down to –40°C)

Maintains cling and flexibility under deep-freeze conditions.

Ideal for frozen food trays, frozen bakery and cold-chain logistics.

Performance Advantages

Compared with a single-layer PET sheet, laminated PET sheet rolls offer:

Higher mechanical strength

PET substrate provides high tensile strength, stiffness and toughness; functional layers can further tune impact and forming behavior.

Enhanced chemical resistance

Good resistance to many acids, alkalis and solvents, suitable for food, household and some industrial packs.

Upgraded barrier properties

Functional layers (such as barrier films or coatings) significantly improve resistance to water vapor, oxygen and gases, supporting longer shelf life.

Improved surface performance

Wear resistance, anti-static, easy-to-clean, easy-peel, anti-fog… surface properties can be tailored by selecting the right functional films and treatments.

Recyclability potential

PET-based structures are generally easier to collect and recycle compared with mixed-material packaging, supporting your sustainability targets.

Typical Applications

Laminated PET sheet rolls from WANSYN are used in:

Food & Beverage Packaging

Thermoformed food trays (meat, seafood, sushi, fruit, desserts)

Ready-meal and chilled/frozen meal trays

Lidding films, easy-peel tops and high-barrier bottoms

Confectionery & Gift Packaging

Metallic gold trays for chocolate, biscuits and seasonal gifts

Iridescent and holographic inserts for luxury gift boxes and cosmetics

Electronics & Industrial Packaging

ESD and anti-static trays for electronic components

Protective and barrier packaging for delicate parts

Medical & Healthcare Packaging

Blister packs and trays with good chemical and barrier resistance (to be matched per project).

If you share your tray drawings, forming method and filling process, we can recommend the most suitable laminated PET structure.

Processing & Converting

Compatible with thermoforming, vacuum forming and pressure forming

Suitable for die-cutting, punching, slitting and sheeting

PET substrate thickness typically 0.25–2.0 mm, functional layer thickness usually 0.01–0.20 mm, adjusted according to performance needs

Our technical team can provide reference forming temperatures, preheating recommendations and thickness suggestions based on your machine type and mould depth.

Production process of laminated PET sheet roll

The production process of the laminated PET sheet roll mainly includes the following steps:

PET substrate preparation: PET substrate can be prepared by extrusion, film blowing, casting and other methods.

Functional film preparation: Functional film can be prepared by biaxial stretching, coating, deposition and other methods.

Adhesive coating: Apply adhesive on the PET substrate and functional film.

Lamination: The PET substrate and the functional film are laminated together by hot pressing, cold pressing and other methods.

Cooling and shaping: The laminated material is cooled and shaped.

Cutting: Cut the laminated PET sheet roll into the required size and shape.

Purchase Notice

|

Packing way |

Packed in roll or flat sheet,50-150kg/roll or according to specific requests from clients. |

|

Packing material |

Inner PE film+ palletized for extra reinforcement if necessary. |

|

Shipping marks |

Neutral packing with printed marks. |

|

Delivery time |

7~15 days since receipt of PO and down payment. |

|

Freight |

Sea/Rail Way(FCL & LCL) or air freight. |

|

Special size |

We provide cutting services for special sizes. |

|

Payment Accepted |

D/A, D/P, T/T, L/C, Westunion etc. |

Why WANSYN Industry?

Integrated product portfolio:

Eco-friendly PVC stabilizers and functional PET/PS/PP sheets – deeper understanding from additives to finished packaging.

Application-driven solutions:

We don’t just sell material; we help you choose the right structure, thickness and surface for chocolate trays, sushi trays, meat trays, frozen foods and technical parts.

Stable quality & export experience:

Proven records with converters and traders in Asia, Europe and other regions, with full export documentation and third-party test support when needed.

Technical support:

From sample selection to trial production, our team can assist with sheet choice, forming window and line optimization to reduce waste and improve yield.

Ready to Develop Your Own Laminated PET Tray or Lidding Solution?

Whether you are upgrading from simple PET sheet or looking for a higher-barrier, more eye-catching PET solution, WANSYN Industry can help you design a laminated PET sheet roll tailored to your tray, lid or specialty packaging line.

Contact us with your mould drawings, current material and target market, and we’ll recommend a practical, cost-effective laminated PET solution for your next project.