Design-for-Recycling Thermoforming Sheets: Mono-Material vs Laminated Structures

-

If your market prioritizes recyclability targets, start with mono-material pathways (mono-PET or mono-PP) and only add layers when the shelf-life need is proven.

-

If you need barrier, peel, anti-fog, or metallic effects, laminated structures (PET/CPP, PP/CPP, PET/PE) can deliver performance—just specify the end-use and disposal expectations up front.

-

Always define OTR/WVTR targets, forming depth, and seal behavior before locking structure.

1) Why “Design for Recycling” is now a buyer requirement

Across many markets—especially for exporters—packaging decisions are increasingly tied to recyclability rules and retailer requirements. In the EU, PPWR pushes packaging toward being recyclable/reusable by 2030, making “design for recycling” a practical spec item, not just marketing language.

For thermoforming trays and lids, that means: your material choice should be made with both performance (barrier, clarity, toughness) and end-of-life reality (collection/sorting/recycling compatibility) in mind.

2) Start with the decision tree: mono-material or laminated?

Use this simple rule:

Choose mono-material when:

-

Your target market strongly values recycling compatibility

-

Your product shelf-life is moderate and doesn’t require extreme barrier

-

You want simpler, cleaner material messaging (one polymer family)

Choose laminated when:

-

You must hit a strict shelf-life target (oxygen/moisture sensitive foods)

-

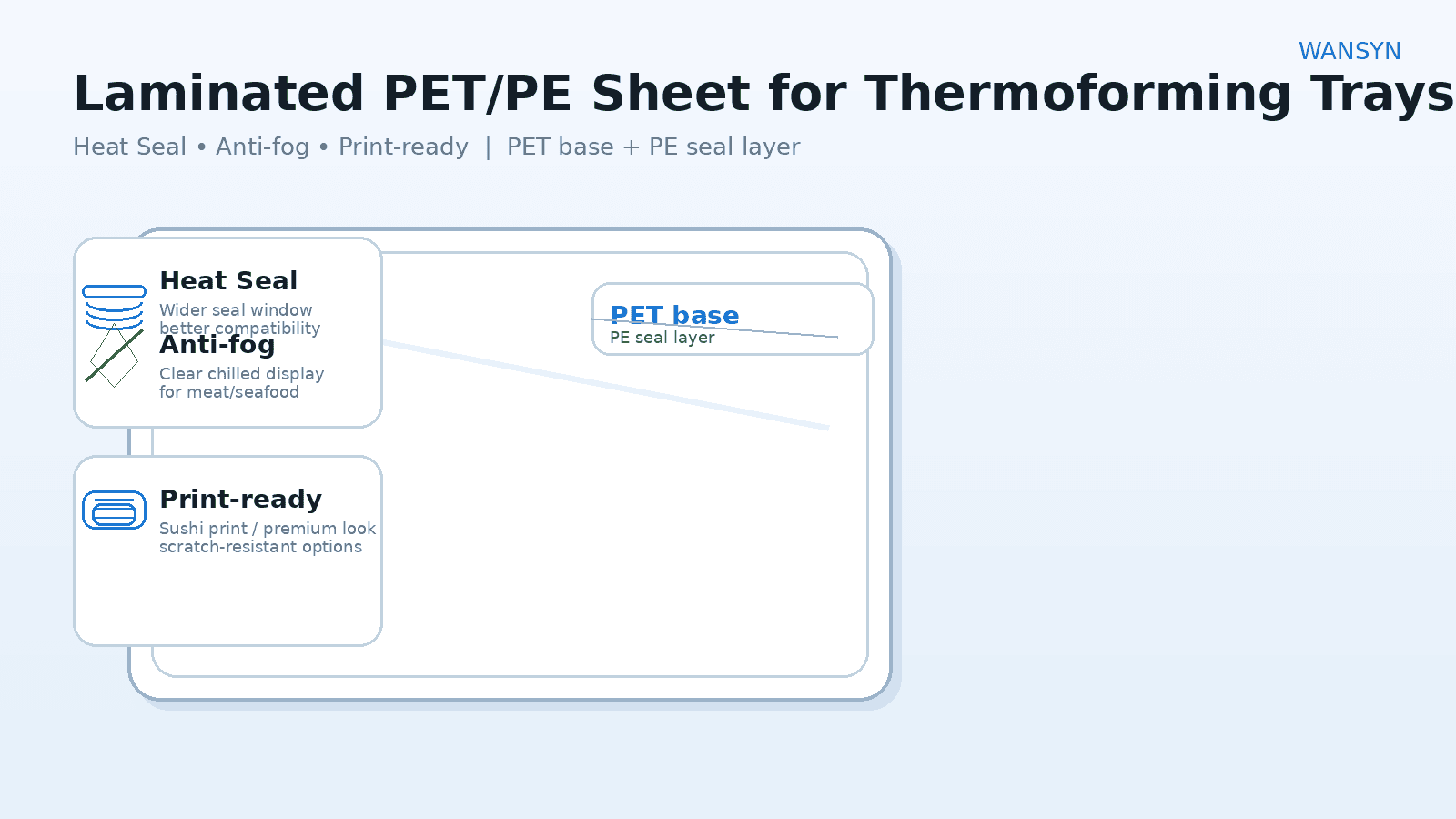

You need controlled peel, anti-fog, print durability, metallic look, or special surface performance

-

Your forming line requires a specific seal layer or surface property

Reality check: Multi-material laminates can be harder to recycle in some systems because layers are not easily separable (this is often discussed for certain PET/PE formats). Treat recyclability as “market- and system-dependent,” and confirm with your local recycling guidance.

3) Performance checklist: what you must define before choosing structure

Before you ask a supplier to recommend PET/CPP vs PET/PE vs PP/CPP, confirm these 8 items:

-

Application: sushi trays, dessert clamshells, chocolate inserts, meat/MAP trays, dairy cups, etc.

-

Forming depth: shallow display tray vs deep cavity insert (affects thinning & barrier after forming)

-

Clarity / gloss: premium display vs functional transport tray

-

Barrier target: OTR/WVTR levels and test conditions (flat vs formed part)

-

Seal & peel: seal window, target tear force, failure mode requirements

-

Anti-fog / chilled display: is fogging a real shelf problem? (fresh/chilled often yes)

-

Low-temperature toughness: chilled/frozen distribution, cracking risk

-

End-of-life expectation: mono-material preference, local recycling guidance, buyer policy

4) Typical thermoforming sheet structure options (and what they solve)

Below are common pathways buyers use:

Option A: Mono-PET (or PET family solutions)

-

Best for: high clarity display, good stiffness, many thermoforming lines

-

Trade-offs: barrier and seal behavior may need tuning depending on product

-

Use when: premium display + recyclability messaging is important

Option B: Mono-PP

-

Best for: toughness, hinge performance, certain food-contact applications

-

Trade-offs: clarity differs from PET; barrier targets may require design work

-

Use when: you want a PP-based mono-material approach

Option C: Laminated PET/CPP or PP/CPP (performance-tuned)

-

Best for: balancing forming stability with seal/peel behavior and functional layers

-

Why it works: you keep a robust base (PET or PP) and tune surface/seal through CPP-based layers

-

Use when: you need easy-peel, better sealing control, surface performance while maintaining forming productivity

Option D: Laminated PET/PE (or PET/PE/functional)

-

Best for: certain sealing systems and cost-performance balancing

-

Trade-offs: depending on local recycling definitions, PET/PE formats can be considered more challenging because of inseparable layers—confirm market requirements early.

5) How to avoid “over-spec”: match barrier to shelf-life

A common mistake is buying ultra-barrier structures for products that don’t need them.

A practical method:

-

Map your product sensitivity (oxygen vs moisture)

-

Set tiered OTR/WVTR targets (standard/enhanced/ultra)

-

Validate barrier after thermoforming (formed corners can thin and change results)

6) What to send your supplier: a one-page RFQ that gets the right structure fast

Copy/paste this to your RFQ:

-

Product: __________ (sushi tray / chocolate insert / meat tray / dairy cup)

-

Structure preference: mono-material preferred? yes/no (why)

-

Thickness: ___ mm (range ok)

-

Width: ___ mm; roll OD: ___; core: ___

-

Forming depth: ___ mm; tool type: vacuum/pressure; line speed: ___

-

Clarity/gloss requirement: high / medium / not critical

-

Barrier target: OTR ___ ; WVTR ___ ; test condition: ______

-

Seal/peel: seal window ___°C; peel force ___ N/15mm (or “consumer easy-open”)

-

Add-ons: anti-fog / scratch resistant / printable / metallized / cold-resistant

-

Compliance: food contact requirement in your market (specify)

7) Related guides

FAQ

Q1: Is mono-material always more recyclable than laminated structures?

Often yes in practice, but recyclability depends on the local collection/sorting/recycling system and the specific format.

Q2: Do I need ultra-barrier for every food tray?

No. Match barrier to shelf-life; “over-barrier” can raise cost without real benefit.

Q3: How do I specify easy-peel correctly?

Define seal window + target tear force, then validate on your sealing equipment.

Q4: When is anti-fog necessary?

If your product is chilled display and fogging affects visibility and sales, anti-fog can be a strong upgrade.

Q5: What info helps a supplier recommend PET/CPP vs PET/PE vs PP/CPP quickly?

Application + forming depth + barrier targets + seal/peel requirement + end-of-life expectation.