Design Guide for Gold-Metallized & Printed PET Sheets for Sushi and Food Trays

1. Why printed & gold-metallized PET trays are everywhere

Walk into any supermarket or convenience store and you’ll see them immediately: glossy black-and-gold sushi trays, metallic dessert cups, and printed snack trays that make even simple products look “premium”.

Behind these designs there is usually one workhorse material: PET thermoforming sheet – often gold-metallized, printed, or both.

For packaging converters and brand owners, the challenge is not just to make a tray that looks beautiful on day one, but to keep:

-

good forming performance on the line,

-

stable color and metallic effect on the shelf,

-

and food-contact safety across cold chain or ambient storage.

In this guide we’ll walk through the key design points when you use gold-metallized and printed PET sheets for sushi and food trays, and how a supplier like WANSYN Industry can support you from sheet design to thermoforming.

2. Where gold & printed PET trays are used

Gold-metallized and printed PET sheets are popular in four major food segments:

-

Sushi & ready-to-eat trays

-

Black or colored base + gold pattern or logo

-

Often combined with clear PET or OPS lids

-

-

Bakery and dessert trays

-

Cakes, tarts, mousse cups, mini desserts

-

Trays may be fully gold or use a printed pattern on a metallic background

-

-

Chocolate, nuts & confectionery

-

Inner trays for gift boxes, seasonal assortments, mooncakes and chocolates

-

-

Premium snack & seasonal packs

-

Holiday gift sets, premium dried fruits, festive assortments

-

In all of these, visual impact at the point of sale is just as important as barrier, stackability and cost.

3. Why PET is a good base for sushi & food trays

Compared with PS or PP, PET offers a combination of:

-

high clarity (for clear lids and windows),

-

good stiffness at relatively low thickness,

-

better oxygen and moisture barrier than PS,

-

good performance in chilled conditions (0–4 °C),

-

and recyclability in many regions.

For gold-metallized trays, PET is especially attractive because:

-

the vacuum-deposited metallic layer adheres well to PET;

-

the sheet can be produced in 0.15–2.0 mm thickness range and 170–1350 mm width to suit different tray sizes and forming lines;

-

it can be combined with easy-peel, high-barrier, printed, coating, iridescent, holographic and cold-resistant options, depending on the project.

4. Step 1 – Choose the right base structure

Before talking about colors and artwork, decide your sheet structure.

4.1 Thickness & stiffness

Typical ranges (can be adjusted case by case):

-

Sushi & RTE trays: 0.35–0.7 mm

-

Dessert cups & mini trays: 0.3–0.6 mm

-

Gift box inner trays (chocolate, mooncake, nuts): 0.3–0.8 mm

Thicker sheet = better stiffness and deep-draw capability, but also higher material cost and heavier stacks.

WANSYN’s PET gold-metallized sheet range covers 0.15–2.0 mm, so you can start thin for light snacks and go thicker for deep trays or large cavities.

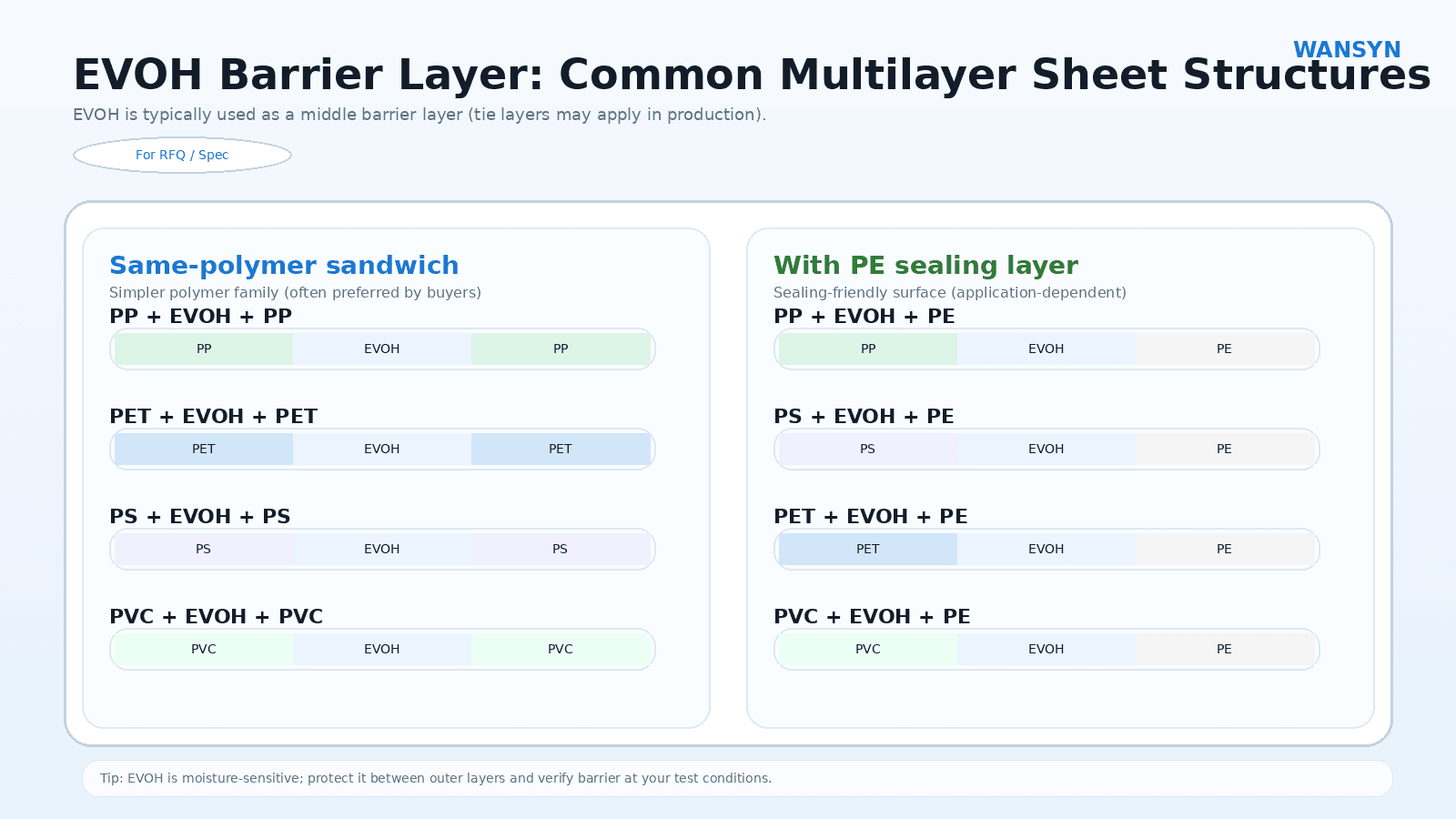

4.2 Mono-layer vs laminated

For many dry or low-risk foods, mono-layer gold-metallized PET is enough.

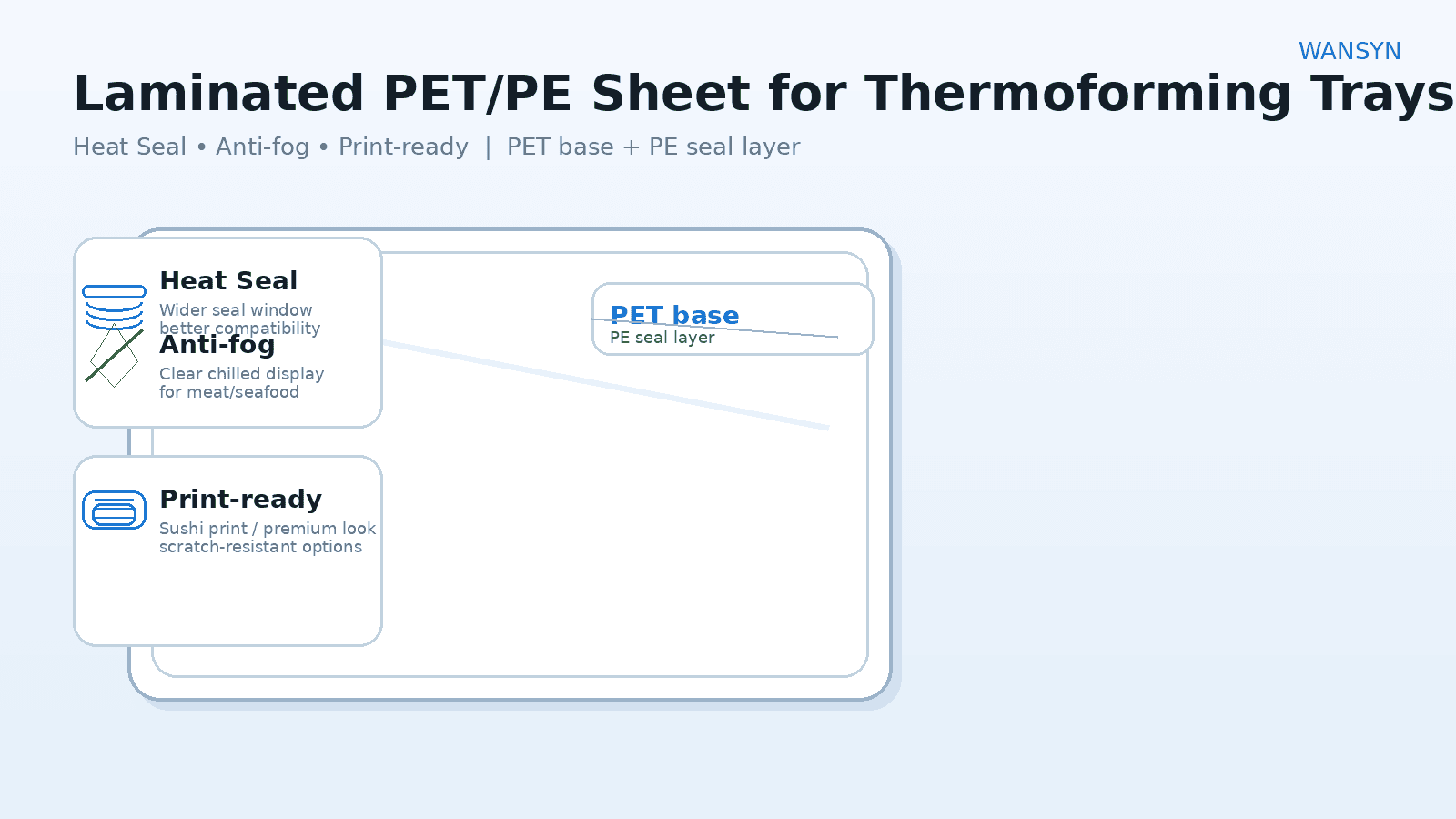

For applications that require higher barrier or heat-sealing, you may consider:

-

metallized PET laminated to sealable PE or other sealant,

-

or high-barrier structured PET for oxygen-sensitive products.

Discuss the filling product, shelf life and sealing method with your sheet supplier early – it can avoid over-engineering or under-performing structures.

5. Step 2 – Decide how you want the metallic & printed effect

Now the fun part: how to combine gold and printing.

5.1 Full-surface gold vs partial metallic

Options include:

-

Full-surface gold

-

Entire tray has a gold background

-

Good for luxury chocolate, mooncakes and gift packs

-

-

Pattern gold (lines, waves, geometric)

-

Gold only in certain areas, with black or color base

-

Very popular for sushi trays (Japanese style patterns, woodgrain, waves, etc.)

-

-

Logo & accent metallics

-

Metallic only under logo or rim area

-

On WANSYN’s side, color can be customized: gold, coffee-gold, silver and other shades, with high-gloss or matte finishes.

5.2 Printed designs – where to put what?

For printed PET, you usually have two printing strategies:

-

Overall background pattern

-

Woodgrain, wave, fabric texture, etc.

-

Works well for sushi or snack trays – it hides minor scratches and gives depth

-

-

Localized graphics

-

Logo, brand blocks, QR codes

-

Should avoid the deepest draw areas to prevent distortion

-

Design rules of thumb:

-

Keep critical text and barcodes away from cavity corners and deep draw areas;

-

Allow bleed around panel edges to compensate for forming stretch and trimming;

-

Use high-contrast colors so the product (sushi, desserts) stands out, not disappears into the background.

5.3 Printed on top or under the metallic layer?

Depending on the structure and printing line, you can:

-

print on the PET side and then metallize, or

-

metallize first and print on top with suitable inks and primers.

For food trays, many converters prefer to keep inks and metallic away from direct food contact by:

-

placing the printed / metallized layer on the outside of the tray,

-

or using a separate inner liner or lid.

Always confirm with your sheet supplier what layer sequence they use and which side is intended for food contact.

6. Performance requirements specific to sushi & chilled food trays

Sushi and chilled foods come with their own set of demands:

-

Cold-chain performance

-

Trays must keep stiffness and gloss at 0–4 °C, often down to –18 °C in logistics.

-

Cold-resistant grades (down to –40 °C) help when conditions are more demanding.

-

-

Food-contact safety

-

Base PET and coatings should meet relevant food-contact regulations.

-

Your supplier should be able to provide food-contact and RoHS/REACH documentation for suitable grades.

-

-

Anti-fog & visibility

-

For sushi, fog on the lid is a bigger issue than the tray,

but using a clean, low-fog tray and a compatible lidding film helps the total look.

-

-

Stackability & denesting

-

Tray design and sheet stiffness need to allow easy de-nesting without scuffing the metallic surface.

-

Sometimes a light textured finish or specific stacking shoulders help avoid scratches.

-

7. Avoiding common problems on the thermoforming line

When switching to gold-metallized or printed PET, converters sometimes face:

7.1 Cracking or whitening of the metallic layer

Symptoms: white stress marks in deep corners, metallic “cracks”, or dull areas.

Mitigation tips:

-

avoid extremely sharp radii; round corners where possible,

-

increase sheet temperature slightly (within safe limits) for better stretch,

-

for deeper trays, choose slightly thicker sheet or a softer grade,

-

discuss draw ratio and mold design with your sheet supplier – they can advise the best thickness window.

7.2 Scratches and scuffing on metallic or printed areas

Symptoms: fine lines, dull zones, or damage during denesting / transportation.

Mitigation tips:

-

use appropriate anti-scratch coatings on the sheet if needed,

-

optimize stacking height and tray nesting design,

-

use interleaving film or adjust palletizing method for premium products.

7.3 Print misregistration vs cavity

When print needs to line up with cavities:

-

share die-cut and cavity drawings with your sheet supplier;

-

allow for machine direction and transverse direction shrink / stretch;

-

start with simpler shapes (bands, central logos) before precise complex alignment.

8. How WANSYN supports converters & brands

At WANSYN Industry, we combine:

-

PET/PS/PP sheet rolls for thermoforming, including:

-

PET gold-metallized sheets/rolls

-

PET printed sheets/rolls

-

PS gold-metallized sheets/rolls

-

Sushi-grade PET/PS/PP sheets

-

with:

-

in-house formulation expertise from our PVC stabilizer business, and

-

experience working with high-barrier, easy-peel and printed packaging structures.

For gold-metallized and printed PET sheets, we can help you:

-

select thickness, width and roll format tailored to your forming line (0.15–2.0 mm, 170–1350 mm as standard);

-

match gold, coffee-gold, silver or custom colors to your current tray or brand design;

-

combine metallic + print + barrier + easy-peel features in one material family;

-

provide guidance on forming temperature, draw ratio and trimming so trials move faster.

9. Next steps – designing your next sushi or food tray project

If you are planning a new tray for sushi, desserts or premium snacks and want to explore gold-metallized and printed PET sheets, a good way to start is:

-

Share your current tray photos, target look and filling product.

-

Tell us your thermoforming machine type, mold layout and typical thickness.

-

We can then suggest 1–2 candidate sheet structures and send sample rolls for line trials.

To discuss your project or request samples, you can contact the WANSYN team:

-

Tel / WhatsApp: +86 159 5847 3100

-

Email: info@wxchemgroup.com

-

Website: www.wxchemgroup.com