MAP Meat & Seafood Trays: How to Specify OTR/WVTR + Seal Integrity (Microleaks) — and Choose PET/CPP, PP/CPP or PET/PE

-

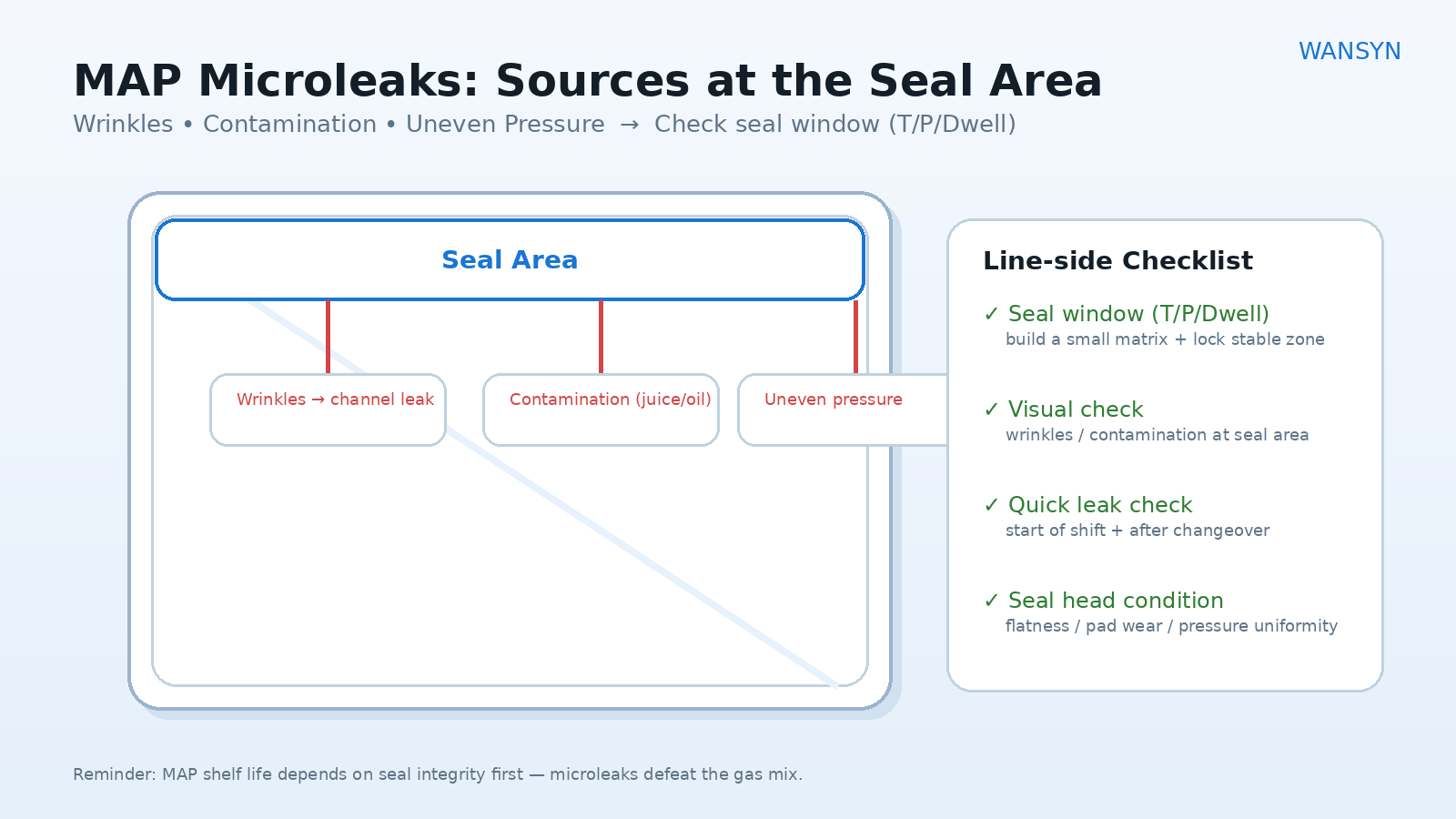

In MAP (Modified Atmosphere Packaging), seal integrity is the #1 quality gate—a microleak can quickly destroy the protective atmosphere and shelf life.

-

Define barrier as OTR/WVTR targets + test conditions (flat sheet vs formed tray), then validate after thermoforming.

-

Most “MAP failures” are not caused by “bad material” alone. They come from microleaks + unstable seal window + contamination/wrinkles + mismatched tray surface vs lidding system.

-

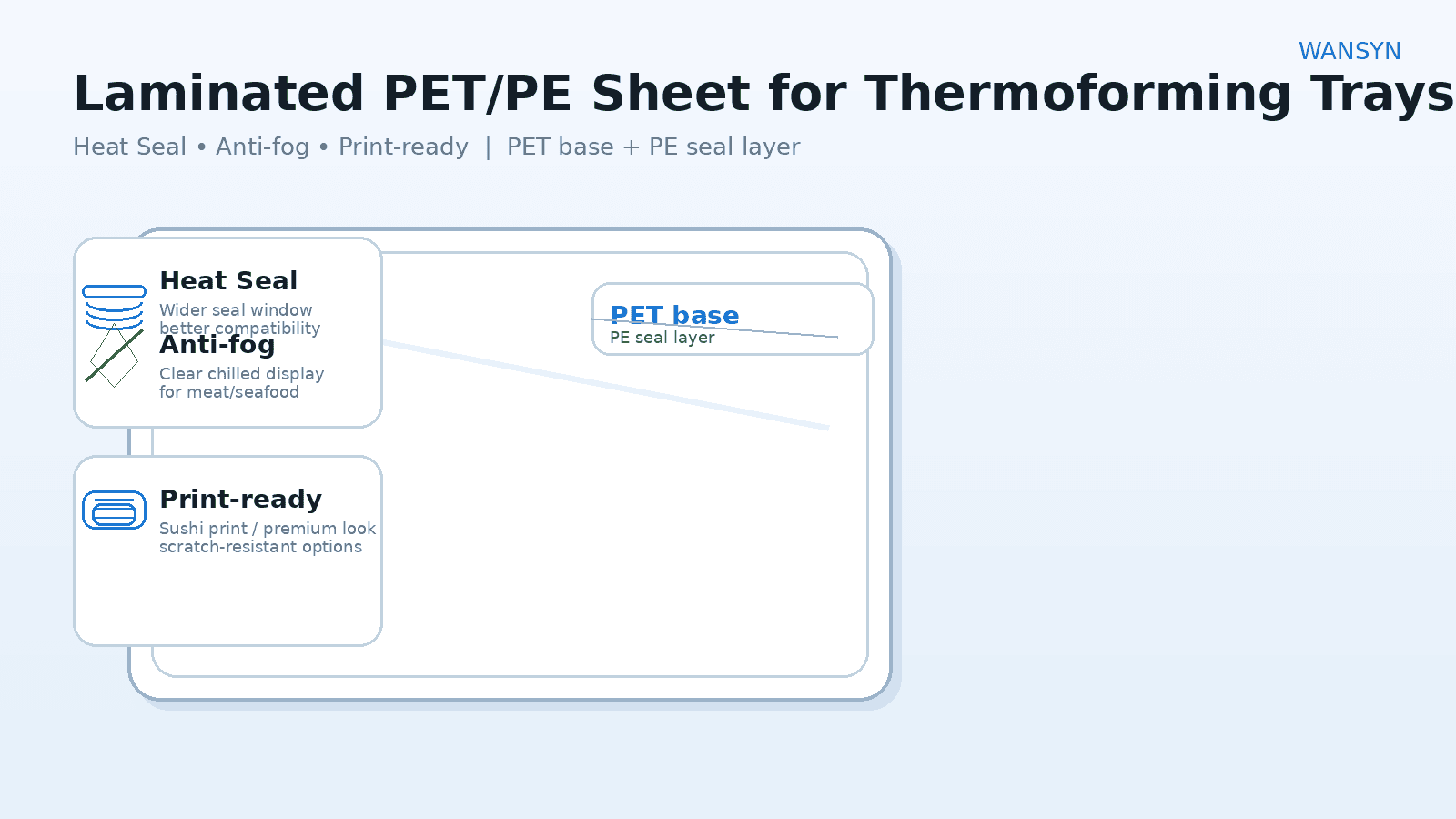

Laminated structures like PET/CPP, PP/CPP, PET/PE help you tune barrier, sealing behavior, easy-peel and anti-fog as one system.

1) Why MAP trays fail in real life (even when the sheet looks OK)

MAP trays extend shelf life by controlling the in-pack gas environment. But all of that work is useless if the pack leaks—a compromised seal lets external air in and the protective gas mix out. That’s why many MAP QC programs treat seal integrity as the first priority, ahead of fine-tuning barrier numbers.

Buyer tip: When you see shortened shelf life, discoloration, or “unexpected spoilage,” don’t only ask for “higher barrier.” First ask:

-

Do we have microleaks/channel leaks?

-

Is our seal window (temperature/pressure/time) stable across shifts?

-

Are wrinkles/contamination causing invisible leak paths?

👉 For line-side symptoms → causes → checks, see: Tray sealing troubleshooting for thermoforming trays (channel leaks, wrinkles, stringing).

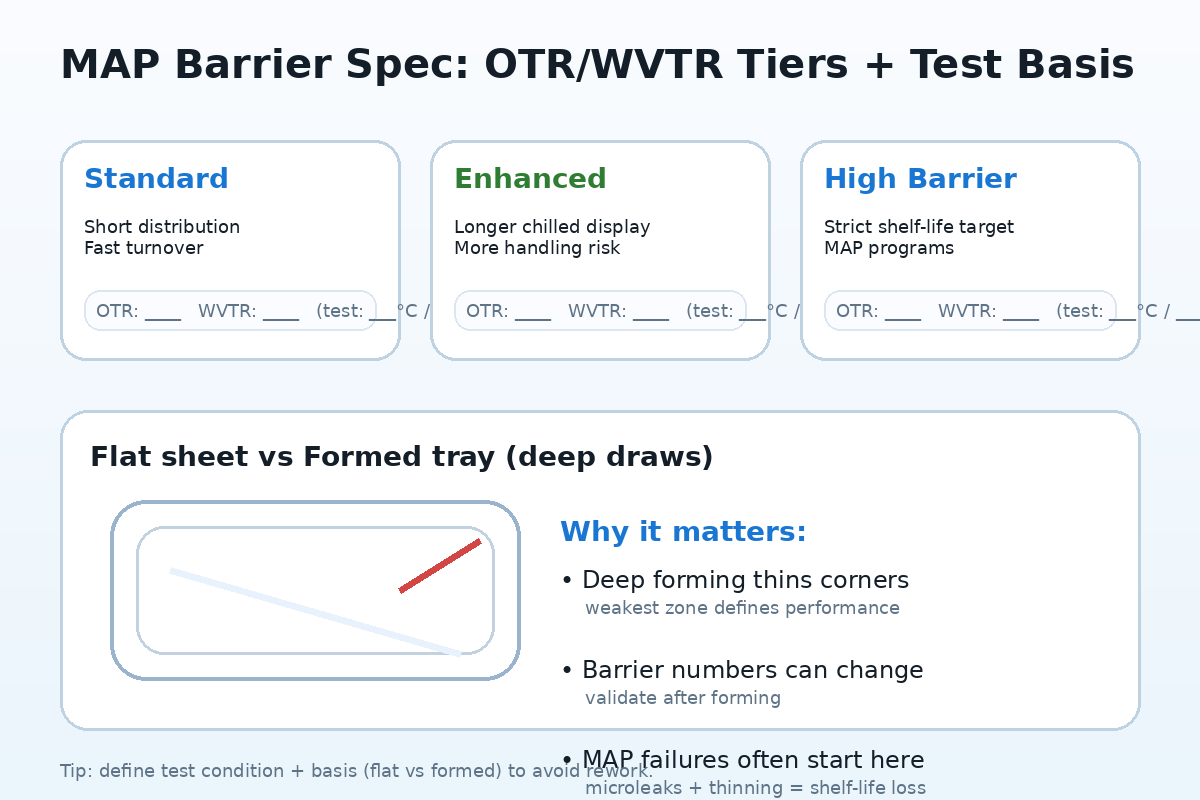

2) Barrier specs that actually work: define OTR/WVTR the “usable” way

OTR and WVTR are key barrier indices that influence shelf life and product appearance.

But buyers often lose time because they request “high barrier” without stating test conditions and whether the target applies to the formed tray.

2.1 What to specify (minimum)

-

OTR target + test condition (temperature/RH)

-

WVTR target + test condition (temperature/RH)

-

Measure on flat sheet or formed tray?

-

Deep forming thins corners and can change effective barrier at the weakest zones.

-

2.2 A practical tier approach (reduces over-spec and cost)

Instead of guessing one “perfect” number, define barrier in tiers:

-

Standard: short distribution + fast turnover

-

Enhanced: longer chilled display / more handling risk

-

High barrier: MAP projects with strict shelf-life targets

👉 If you’re building a supermarket program (meat/seafood/sushi) and need barrier + anti-fog + easy-peel + print durability, this guide helps define the full spec:

Supermarket meat, seafood & sushi trays: barrier, anti-fog, easy-peel & printed laminated sheets.

3) Seal Integrity (Microleaks): what to check before “changing materials”

3.1 The most common microleak sources in MAP trays

-

Channel leak from wrinkles at the seal area

-

Contamination (protein juice, oil, seasoning dust) creating leak paths

-

Pressure non-uniformity (seal head flatness / worn pads / uneven platen)

-

Uncontrolled seal window (temperature/pressure/dwell drift)

-

Mismatch between tray sealing layer/surface and lidding film

3.2 Two fast improvements that often beat “new material”

-

Build a small seal window matrix (Temp × Pressure × Dwell) and lock down the stable region.

-

Add visual + routine leak checks at the start of each shift and after changeovers.

👉 If your project also needs easy opening, do not write “easy-peel” only—spec it:

Easy-peel lidding: seal window & target tear/peel behavior.

4) Choosing PET/CPP vs PP/CPP vs PET/PE for MAP trays (buyer-friendly)

Below is a practical selection logic (final choice must be validated on your line):

Option A — PET/CPP laminated thermoforming sheet

Use when: you need a balanced package: clarity + stable forming + tuned sealing surface + optional print/anti-fog/barrier.

Why buyers pick it: it often delivers a wider processing window when sealing and appearance must both be controlled.

Option B — PP/CPP laminated thermoforming sheet

Use when: PP-based systems are preferred, with stronger emphasis on heat resistance and toughness-focused handling performance, while still tuning sealing behavior as a system.

Option C — PET/PE laminated thermoforming sheet

Use when: your sealing system is PE-friendly, and you want a cost-performance balance while meeting the required barrier + sealing stability.

👉 For “mono vs laminated” sustainability discussions and how brands frame requirements, this reference helps:

Design-for-Recycling: mono-material vs laminated thermoforming sheets.

5) MAP tray success checklist

If you want a fast, accurate recommendation, send these up front:

-

Product: beef/poultry/salmon/shrimp / fat level / liquid release

-

MAP gas mix (if defined) + target shelf life

-

Storage: 0–4°C chilled or frozen (if both, state both)

-

Tray design: depth, corner radius, flange width

-

Barrier tier target (Standard/Enhanced/High) + test basis (flat vs formed)

-

Sealing method + equipment + seal head type

-

Seal targets: “no leaks” definition + peel mode requirement (if any)

-

Optional: anti-fog, easy-peel, printing, metallic looks

6) Copy-ready RFQ template

Copy/paste and fill in:

Application: MAP meat / seafood tray (chilled)

Product details: __________ (oil/liquid level: )

Target shelf life: ___ days; distribution: local / export / long-haul

Storage temp: 0–4°C ( days) / optional freezing ___°C

Tray geometry: depth ___ mm; corner radius ___ mm; flange ___ mm

Preferred structure: PET/CPP / PP/CPP / PET/PE (or “please recommend”)

Sheet thickness: ___ mm; width/OD/core: ___ / ___ / ___

Barrier target: OTR ___; WVTR ___; test condition: ___; basis: flat sheet / formed tray

Seal integrity requirement: no channel leaks; leak test method (if any): ___

Sealing equipment: ___; temp range: ___°C; pressure: ___; dwell: ___ s

Easy-peel (if required): yes/no; peel mode: clean / no stringing / no residue; target peel force: ___

Anti-fog: yes/no; chilled display: ___ days

Printing/appearance: none / brand print / sushi print / gold look

Compliance: food contact requirement + market: ___

Annual volume: ___; destination port: ___

FAQ

Q1: Do MAP trays always require “high barrier”?

Not always. Start from shelf life + distribution reality, then choose a barrier tier. Over-specifying inflates cost without fixing microleaks.

Q2: Why does MAP shelf life drop even with good OTR/WVTR numbers?

Because seal integrity dominates. A microleak can defeat the gas environment quickly.

Q3: Should we test barrier on flat sheet or formed trays?

For deep trays, validate on formed trays—corners are often the weakest zone.

Q4: Can one structure handle barrier + anti-fog + easy-peel + printing together?

Yes—this is exactly where laminated structures (PET/CPP, PP/CPP, PET/PE) help tune performance as a package system.

Need help matching a MAP tray spec?

Send the RFQ template + tray drawing and your sealing setup. We’ll recommend a laminated structure (PET/CPP, PP/CPP, PET/PE), provide trial rolls/sheets, and support forming + sealing validation.