How to Prevent Freezer Cracking in Thermoformed Meat & Seafood Trays (-20°C Cold Chain)

Cold chain packaging may look fine at room temperature—until it goes through real logistics: -20°C freezing, stacking, vibration, and drops. Then you see typical failures:

-

Freezer cracking (often at corners / deep-draw zones)

-

Corner whitening (stress whitening / micro-deformation)

-

Drop breakage after freezing or chilled handling

If you’re searching freezer cracking thermoforming or low temperature toughness tray, the key is this: failures are usually driven by a system of thickness distribution + residual stress + low-temperature brittleness + handling loads—not a single factor.

-

The #1 driver is corner thinning caused by high draw ratio and non-uniform forming thickness.

-

Low temperature reduces ductility, and residual stress makes micro-cracks/crazing grow into visible cracks.

-

The fastest improvement path is: (1) improve thickness distribution, (2) reduce residual stress, (3) validate on formed trays under real cold-chain conditions.

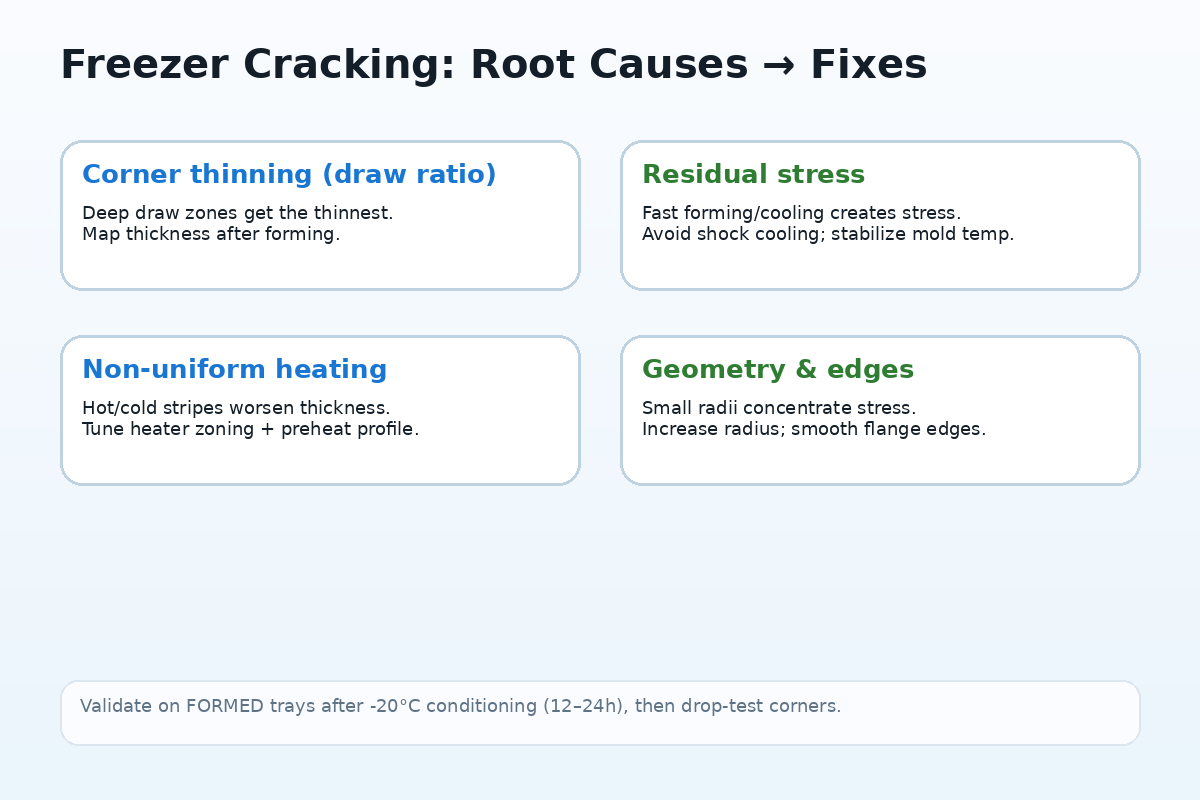

1) Root causes of cracking at -20°C

Cause A — Corner thinning from draw ratio (most common)

Thermoforming stretches the sheet; corners and deep draws become the thinnest, weakest zones. Draw ratio is widely used to estimate minimum thickness and thinning risk.

Common signs

-

Cracks start at corners/radii

-

Failures increase with deeper trays

-

Flat-sheet tests pass, formed-tray tests fail

Cause B — Low-temperature brittleness + residual stress

At low temperature and higher strain rates, polymers behave more brittle (less time for yielding). Residual stress can lead to crazing/cracking and eventual failure.

Common signs

-

Whitening before cracking

-

Cracks appear after cold storage/transport, not immediately

Cause C — Non-uniform heating and cooling

Uneven heating increases thickness variation and stress; cooling inconsistencies also raise internal stress and distortion risk.

Cause D — Geometry stress concentration

Small corner radii and sharp flange edges concentrate stress—especially dangerous at freezer temperature.

2) Forming tips to improve low-temperature toughness (before changing material)

Tip 1 — Improve thickness distribution at corners

-

Increase corner radius where possible

-

Use/optimize plug assist to pre-stretch and distribute material more evenly, reducing thinning in deep areas

-

Review draw ratio vs starting sheet thickness

Tip 2 — Improve heating uniformity

-

Tune heater zoning (avoid hot/cold stripes)

-

Keep a controlled preheat profile for stable forming

Tip 3 — Reduce residual stress

-

Avoid “shock cooling”; keep mold temperature consistent

-

Balance forming speed and cooling rate

-

Ensure stable web handling and repeatable clamping

Tip 4 — Validate on formed trays under cold conditions

For cold chain packaging, validate after forming and after conditioning:

-

thickness mapping (corner/wall/bottom)

-

cold conditioning at target temp (e.g., -20°C for 12–24 h)

-

drop tests (corner-first is critical)

3) Material & laminated structure approaches

Note: “better at low temperature” depends on grade, formulation, and tray geometry. Use structure selection to widen your success window, then validate in your actual line.

Option 1 — Toughness-focused systems (PP/CPP laminated sheet rolls)

PP is often described as more flexible and impact-absorbing than PET in many packaging uses, which can help in handling/transport scenarios—but final performance must be proven in your formed tray + cold tests.

When it helps

-

Projects prioritizing cold-chain handling robustness

-

Need to integrate printing/other functions as a system

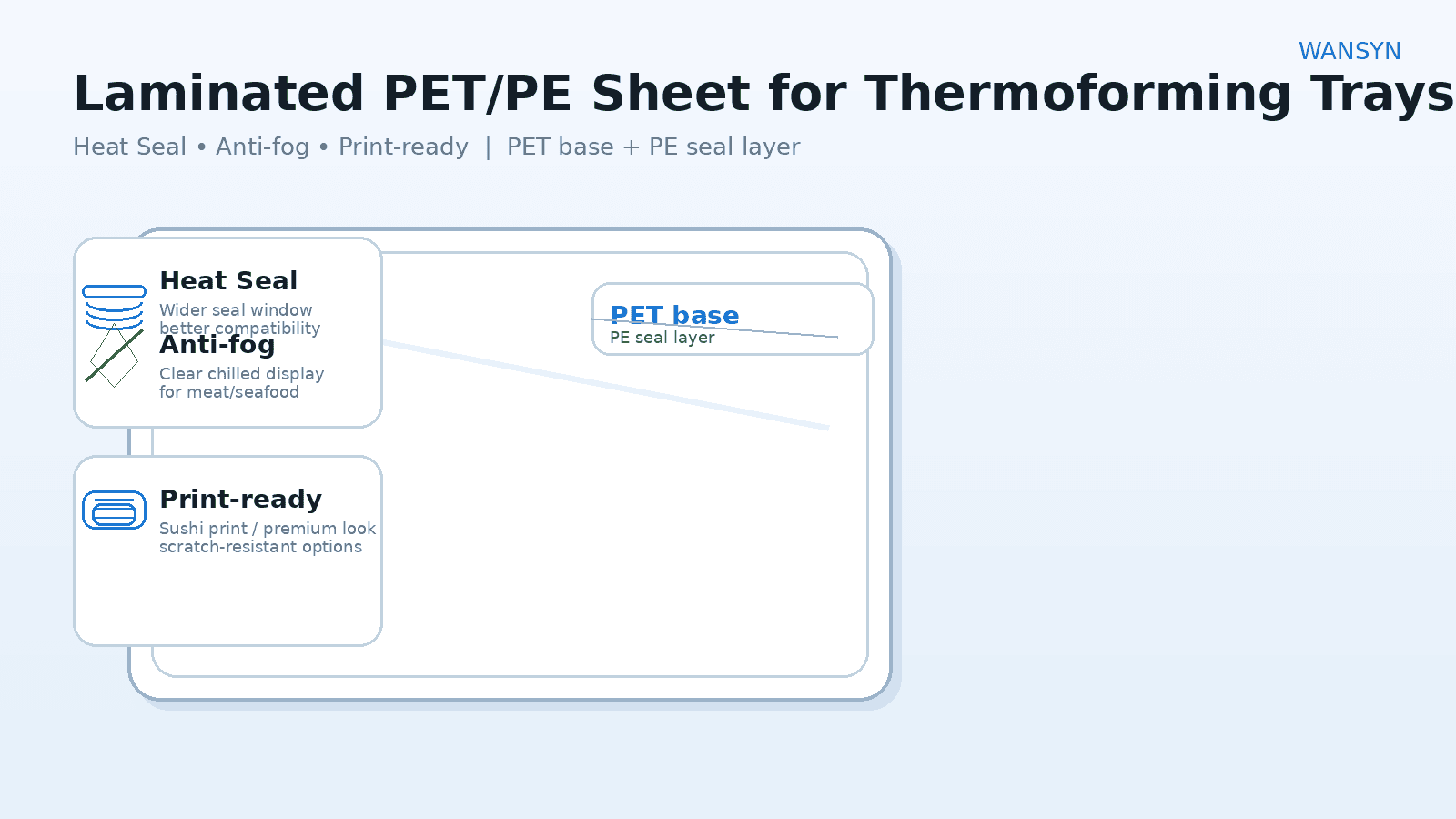

Option 2 — PET-based laminated systems (PET/CPP or PET/PE)

PET is widely used for clear display packaging; PET laminated solutions can be engineered for functional needs (printing, barrier, anti-fog compatibility), but require tight control of thickness distribution and cold-impact targets.

When it helps

-

Clear display and branded trays

-

System integration with barrier / anti-fog / printing requirements

Important: Always check compatibility with your lidding/sealing setup—seal integrity and peel behavior can shift under cold conditions.

4) Recommended test plan for “cold chain packaging”

Define your test plan clearly:

-

target temperature: ___°C (e.g., -20°C)

-

conditioning time: 12–24 h

-

drop test: height + orientation (corner-first)

-

stacking load: carton/pallet simulation

-

acceptance: no cracks; define whitening tolerance if needed

5) Copy-ready RFQ checklist

Application: meat / seafood tray (chilled / frozen)

Cold chain temperature: ___°C; storage time: ___ days

Tray design: depth ___ mm; corner radius ___ mm; flange width ___ mm

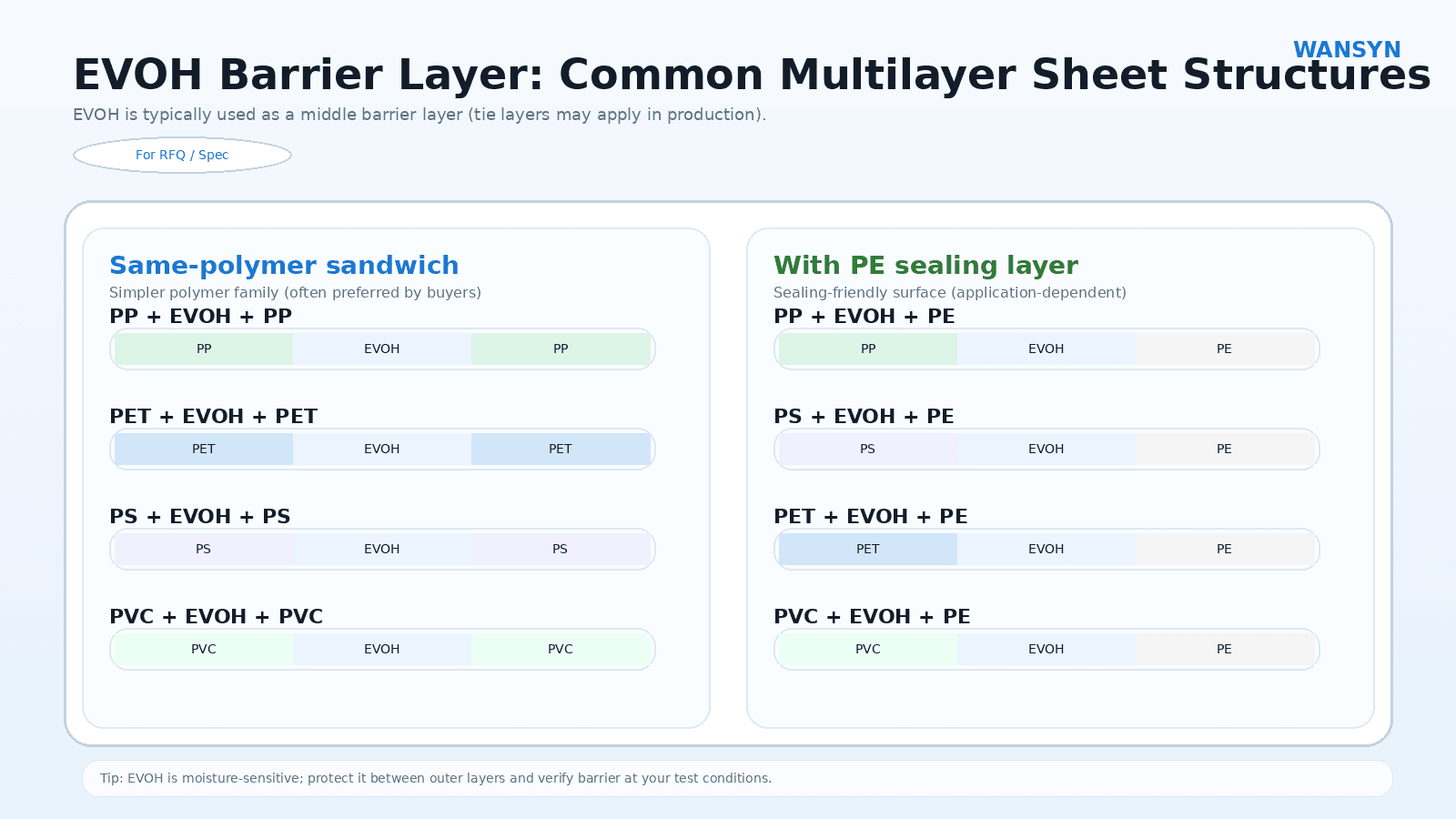

Preferred structure: PP/CPP / PET/CPP / PET/PE (or “please recommend”)

Sheet thickness: ___ mm; roll width/OD/core: ___ / ___ / ___

Forming: vacuum/pressure; plug assist yes/no; line speed ___

Failure: corner cracking / whitening / drop breakage

Testing: conditioning ___ h at ___°C; drop height ___

Lidding/sealing: heat seal / VSP; (if easy-peel) peel target ___

Functions (optional): barrier OTR/WVTR ___; anti-fog yes/no; printing yes/no

Compliance: food contact requirements for your market ___

FAQ

Q1: Why does it pass at room temp but crack in the freezer?

Low temperature reduces ductility; forming creates thin corners and residual stress, so the formed tray becomes far more sensitive.

Q2: Fastest forming fix?

Improve corner thickness distribution (plug assist, heating uniformity, radius) and reduce residual stress.

Q3: Should I test flat-sheet impact only?

No—validate on formed trays after cold conditioning for realistic cold chain packaging.

If your thermoformed meat/seafood trays crack or whiten in freezer logistics, we can recommend a matched laminated sheet solution (PP/CPP, PET/CPP, PET/PE) based on your tray depth, thickness distribution target, and sealing system—plus samples and application guidance.