Laminated Sheet Rolls for Food Thermoforming: PET / PP / PS Guide + RFQ (2026)

Thermoforming tray projects rarely fail because “the base material is wrong.”

They fail because the real requirements were never written down: sealing behavior, peel experience, anti-fog clarity in chilled displays, shelf-life barrier targets, print durability, premium metallic appearance, and cold-chain toughness.

That’s why many buyers have moved from “Can you supply a sheet?” to:

“Can you deliver a validated, repeatable performance package—consistently?”

This guide explains how to choose laminated sheet rolls based on PET / PP / PS, how to match functional options (barrier / anti-fog / easy-peel / printing / metallic), and how to send an RFQ that gets fast, accurate quotes and sampling.

1) What is a laminated sheet roll?

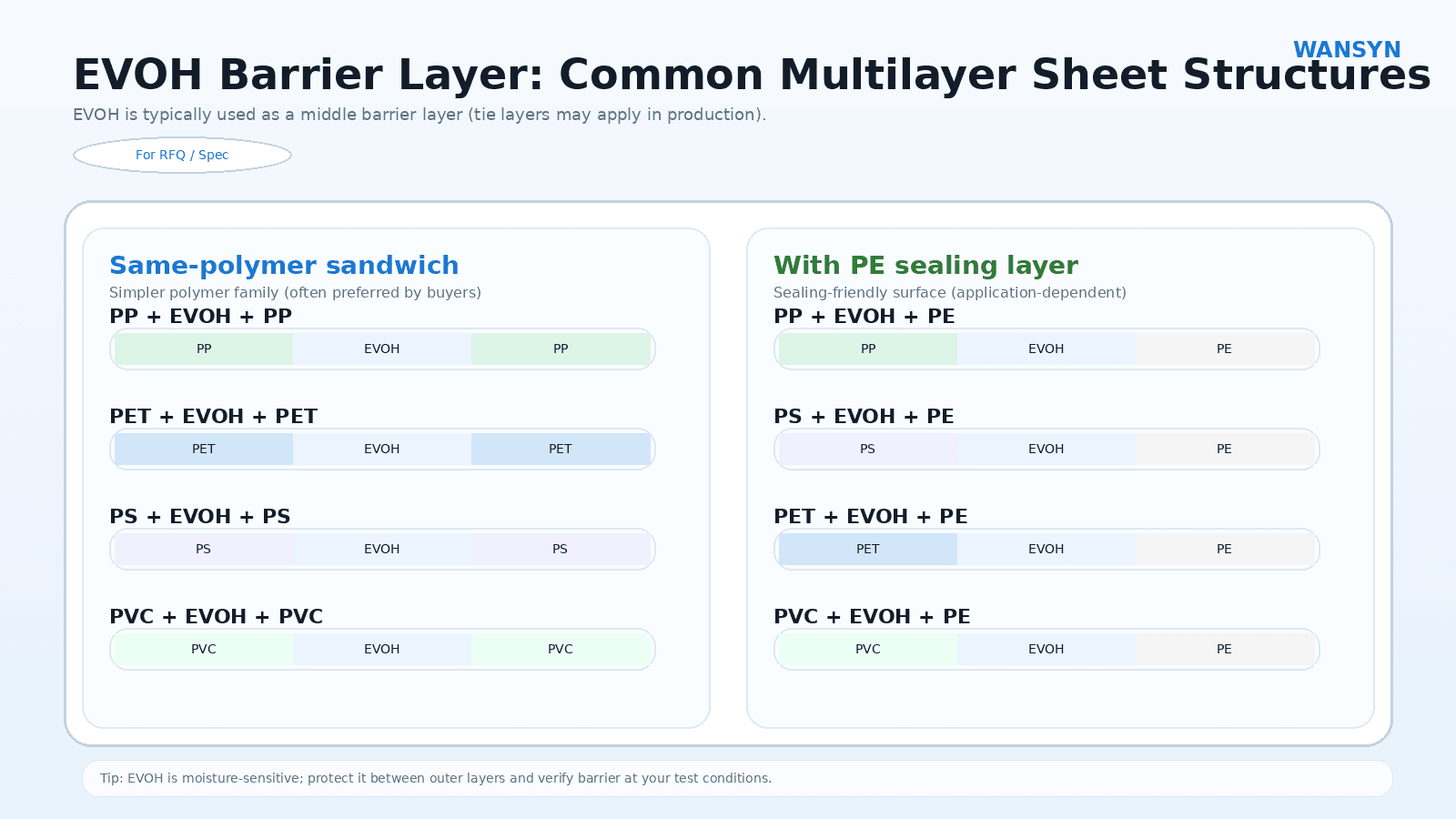

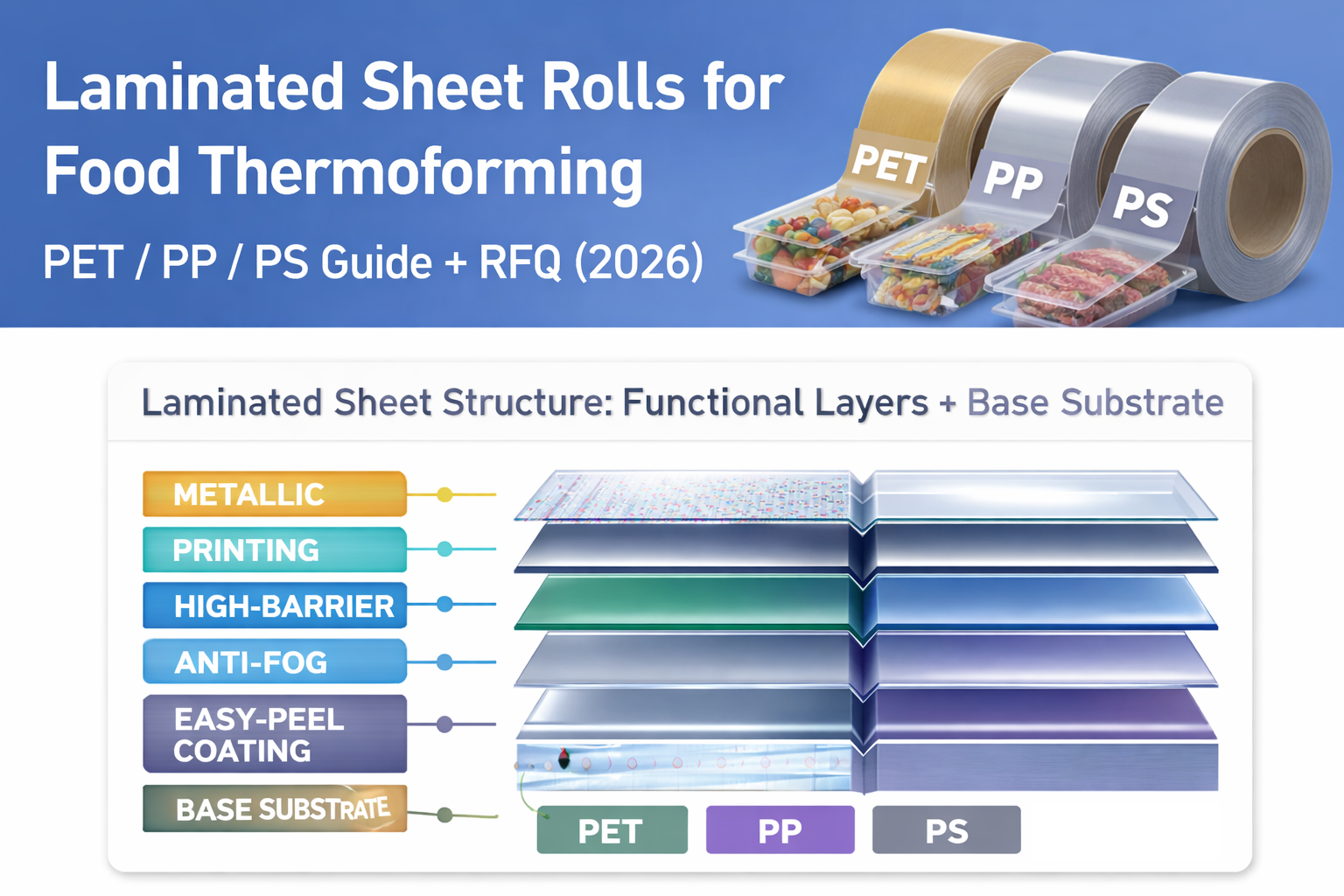

A laminated sheet roll is typically built from:

-

Base substrate (PET / PP / PS) – provides stiffness, clarity, strength, heat resistance, and forming stability

-

Functional layer(s) – printing, metallic look, barrier, anti-fog, scratch resistance, easy-peel surface, etc.

-

Adhesive layer – bonds layers and stabilizes performance consistency from batch to batch

In one sentence: the substrate defines forming and base properties; the functional layer defines shelf performance and user experience.

2) Why laminated structures are widely used for modern food trays

Retail and ready-to-eat packaging often needs multiple outcomes at the same time:

-

clear display (anti-fog)

-

freshness control (barrier)

-

easy opening (easy-peel / controlled peel)

-

shelf impact (printing / premium metallic looks)

Laminated structures make it easier to combine these requirements with a stable processing window—reducing trial-and-error during thermoforming and sealing validation.

3) Start with the right decision framework (before you pick PET/PP/PS)

Instead of choosing by material name, define the project requirements in this order:

-

Application: sushi / meat / seafood / dessert / MAP tray / gift insert

-

Temperature conditions: chilled? -20°C frozen? hot-fill? (project-dependent)

-

Sealing & opening: standard heat seal? easy-peel needed? “clean peel” required?

-

Display requirements: clarity? gloss/matte? printing? metallic look?

-

Shelf-life target: barrier requirement (OTR/WVTR) and test condition

-

Recycling / compliance: market expectations and brand requirements

If you write the requirements clearly, the structure selection becomes much faster and more accurate.

4) PET vs PP vs PS: how to choose the base substrate (quick guidance)

Below are practical, buyer-friendly directions (final selection should be validated by trials):

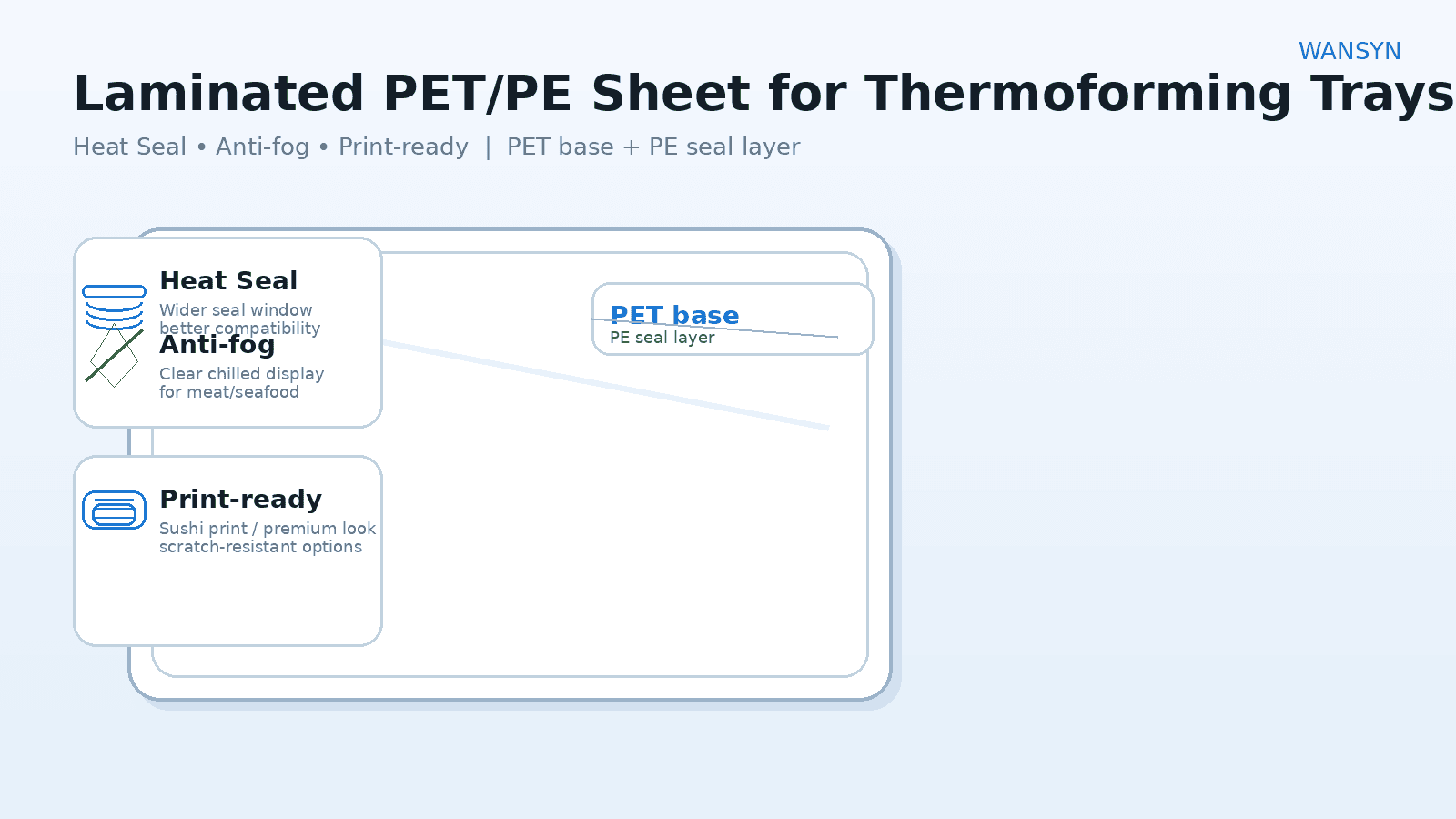

A) PET-based laminated sheet rolls (rigid, clear, premium appearance)

Often chosen when you need: high clarity, gloss consistency, strong stiffness, and a premium look for food trays and decorative packaging.

Deep dive (recommended):

→ Laminated PET sheet rolls for food thermoforming: structures & options

B) PP-based laminated sheet rolls (heat resistance focused)

Often selected when projects require higher heat resistance and compatibility with specific sealing systems and applications.

Next step (suggested content):

→ Laminated PP sheet rolls: structure selection & sealing match (future pillar)

C) PS-based laminated sheet rolls (market fit & cost-performance for specific trays)

Often used where PS is already established in the market and converters need compatibility with existing tray systems, with a clear cost-performance target.

Next step (suggested content):

→ Laminated PS sheet rolls: applications & structure matching (future pillar)

5) Common laminated structures (name + what they solve)

To keep selection practical, use “function first”:

-

PET/CPP – often chosen for balanced appearance + processing stability with tuned surface performance

-

PP/CPP – typically used where heat resistance and sealing system matching are key

-

PS/CPP – used in certain markets for compatibility and cost-performance

-

PET/PE, PP/PE, PS/PE – selected when sealing-layer matching and cost targets are priorities (confirm recycling expectations early)

Tip: Don’t lock a structure only by name—validate it against your sealing film, forming depth, and display requirements.

6) Application shortcuts: what to prioritize by tray type

Sushi & ready-to-eat trays

Usually driven by brand appearance + clean opening (printing/metallic + easy-peel), and often anti-fog for chilled display.

Meat & seafood trays (chilled / MAP)

Often driven by barrier + anti-fog + sealing stability to protect freshness and appearance.

Dessert / chocolate / gift inserts

Often driven by premium metallic looks + forming consistency, with scratch resistance and print durability.

Frozen / cold chain trays (-20°C)

Cracking, corner whitening, and drop failures are often caused by a combination of:

thickness distribution (corner thinning) + residual stress + low-temperature brittleness + handling loads.

Start by checking thickness distribution and stress control, then validate structure and forming settings.

7) Functional options

For website and Alibaba listings, structure your “options” like a menu:

-

Metallic: gold, champagne gold, rose gold, silver, etc.

-

Printing: custom patterns for sushi/food trays and brand designs

-

High-Barrier: for MAP trays and shelf-life upgrades

-

Anti-Fog: clear display in chilled cabinets

-

Easy-Peel: controlled peel, clean opening experience

-

Coating / Scratch Resistance: better rub resistance and surface durability

-

Cling / Cold-Resistant Options: for cold-chain handling and low-temperature performance

These terms match how buyers describe requirements—not just material names.

8) Copy-ready RFQ checklist

To recommend the right structure quickly, please share:

-

Application: sushi / meat / seafood / dessert / chocolate insert / clamshell / MAP tray

-

Base preference: PET / PP / PS (or “not sure—please recommend”)

-

Mono-material requirement: yes/no (and why)

-

Thickness: ___ mm (acceptable range)

-

Width & roll format: width ___ mm; roll OD ___; core ID ___; roll weight ___

-

Forming: vacuum / pressure / plug assist; forming depth ___ mm; line speed ___

-

Appearance: clarity, gloss/matte, color, metallic effect, print pattern

-

Functional needs (select): barrier / anti-fog / easy-peel / scratch resistance / low-temp toughness

-

Sealing system: lidding film type, sealing temp range, pressure/time, target failure mode

-

Cold chain: chilled / -20°C frozen / drop test requirement

-

Compliance: food-contact requirement + target market

-

Annual volume + destination port

This checklist reduces repeated sampling and prevents spec mismatch.

9) FAQ

Q1: Can you match our existing gold shade and gloss?

Yes. Share a physical sample or reference, and we can adjust tone and gloss, then provide trial rolls for confirmation before mass production.

Q2: Will laminated sheet rolls run on our current thermoforming line?

In many cases, yes—because the substrate provides forming stability while functional layers tune surface performance. Share forming depth and line type to confirm.

Q3: Why do easy-peel and sealing issues happen even when the material looks fine?

Most problems come from incomplete specifications, unstable sealing parameters (temperature/pressure/time), contamination/wrinkles, and mismatch between tray structure and lidding system—not simply “bad material.”

Q4: What’s the fastest way to address cracking at -20°C?

Start by improving thickness distribution and reducing residual stress; validate on formed trays under real cold-chain conditions, then fine-tune structure and forming settings.

If you’re sourcing laminated sheet rolls for food thermoforming (PET/PP/PS with printing, metallic, barrier, anti-fog, easy-peel, or cold-chain toughness), send the RFQ checklist and tray drawing. We’ll recommend the structure and provide trial rolls for validation.