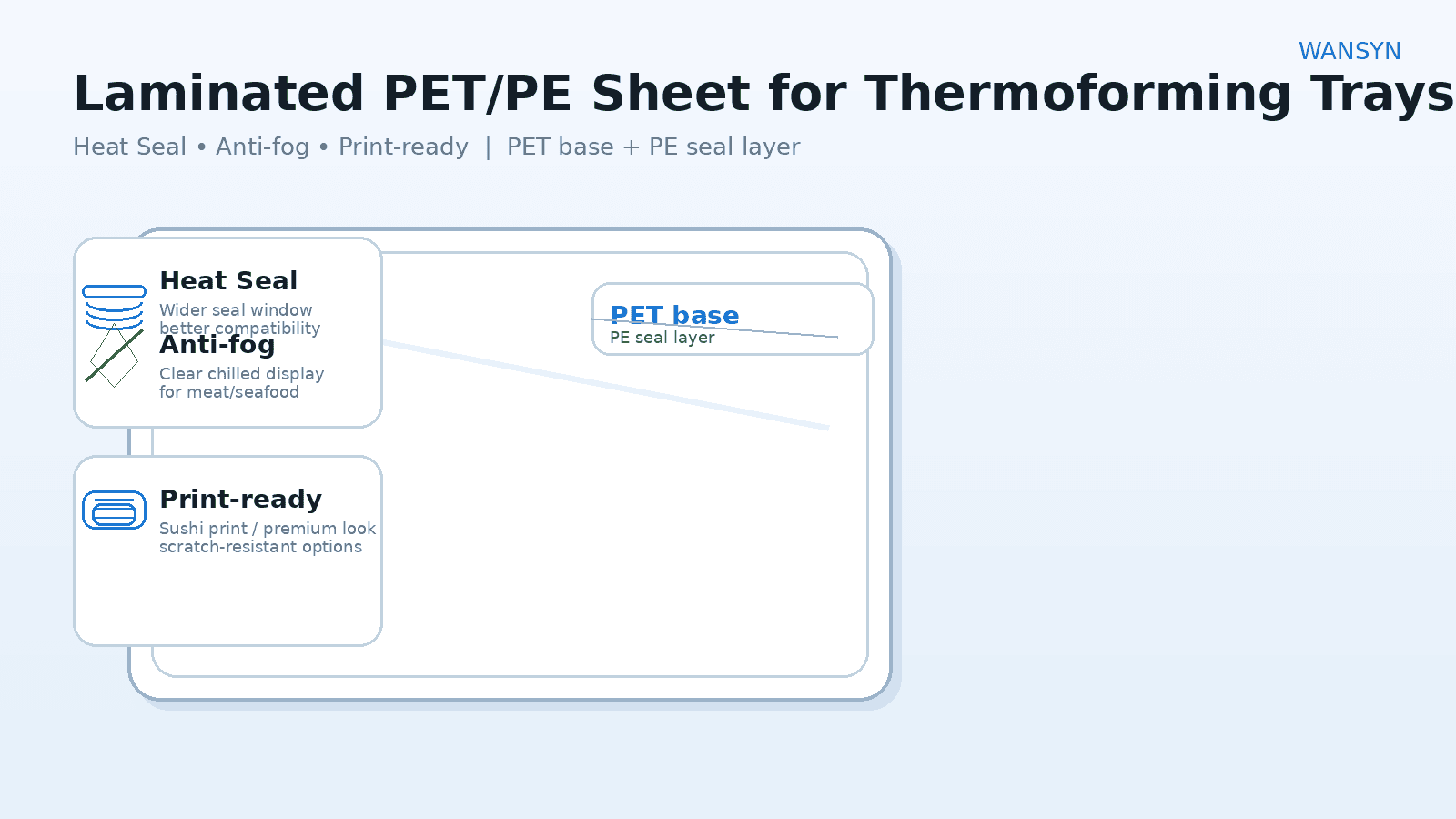

Laminated PET/PE Sheet Roll for Thermoforming

How Buyers Specify Sealing, Printing & Anti-Fog—And When to Upgrade to PET/CPP or PP/CPP

If you source thermoforming sheet rolls for supermarket meat trays, seafood trays, sushi trays, salad and bakery packs, one question shows up again and again:

“Should I use mono sheet, or laminated sheet—and how do I specify it correctly?”

This article is a buyer-focused spec guide for laminated PET/PE sheet rolls (a multi-layer material using PET + PE), including the keywords buyers actually search: thermoforming, sealing, printing grade, gloss/matte/anti-fog, roll or sheet format, custom thickness & width.

1) What is a Laminated PET/PE Sheet?

A laminated PET/PE sheet is a multi-layer plastic material composed of PET and PE:

-

PET layer: high clarity and stiffness (stable forming + premium display)

-

PE layer: heat-sealing properties and moisture resistance (often more forgiving on sealing)

Compared with many single-layer options, PET/PE laminates are often chosen because they balance display quality + sealing stability in real production.

2) Where is Laminated PET/PE Commonly Used?

Typical applications include:

-

Trays, clamshells, lids for food packaging

-

Meat trays, salad containers, bakery packaging, ready-to-eat packs

-

Also seen in medical / blister pack related packaging needs (depending on local requirements)

3) The Buyer Spec That Matters Most: “Seal Window” (Not Just “Seal Strength”)

Many leaks or messy openings are not caused by “bad material”—they come from an unstable seal window.

Seal window = Temperature × Pressure × Dwell time range where you can consistently achieve:

-

hermetic seal (no microleaks)

-

clean opening behavior (if easy-peel is needed)

-

good appearance (no wrinkles / deformation)

Practical Seal-Window Checklist

-

Machine model: ______

-

Lidding film: ______

-

Tray depth & flange width: ______

-

Trial matrix: Temp ___ / Pressure ___ / Dwell ___

-

Record each cell: Pass / Leak / Too strong / Stringing / Wrinkle

If you run MAP or long shelf-life chilled trays, remember: microleaks beat barrier—you can lose shelf performance from sealing first.

4) Finish Options Buyers Search: Gloss vs Matte vs Anti-Fog

Gloss finish

-

Used for premium shelf display clarity

-

Common for meat/seafood retail appearance

Matte finish

-

Reduces glare, improves “premium touch”

-

Useful when branding/label readability matters

Anti-fog coating

-

Helps chilled display clarity (especially in cold cabinets)

-

Best paired with the right structure + sealing system, not “coating only”

5) Printing Grade: Sushi Prints, Premium Look, and Scuff Resistance

For sushi trays and premium thermoformed packs, buyers care about:

-

print sharpness

-

rub/scuff resistance after forming

-

consistent color after heating/forming

If the project is printed sushi trays or premium appearance trays, specify:

-

printing method preference (reverse print + lamination, or protected print)

-

forming depth (deeper draw = higher print stress)

-

scuff target (transport + retail handling)

6) When PET/PE Is Enough—and When to Upgrade to PET/CPP or PP/CPP

PET/PE is a sealing-friendly baseline. But many supermarket projects require a “performance package”:

-

Barrier (OTR/WVTR target)

-

Anti-fog

-

Easy-peel

-

Durable printing

-

Sometimes cold-chain toughness (-20°C)

That’s where WANSYN’s laminated structure menu becomes the engineered upgrade path:

-

PET/CPP: clarity + stable sealing + strong print protection options

-

PP/CPP: cold chain / impact-focused thermoforming (freezer cracking control)

-

PET/PE: sealing-friendly baseline + anti-fog & print-ready options

PET/CPP PP/CPP PET/PE laminated sheets selection

supermarket meat seafood sushi trays laminated sheets

7) Size, Thickness, Roll/Sheet Format—What to Put in an RFQ

Buyers frequently search for “roll or sheet format” and typical thickness ranges.

Copy-ready RFQ template

-

Application: meat / seafood / sushi / bakery / other: ____

-

Structure: PET/PE / PET/CPP / PP/CPP / recommend: ____

-

Thickness: ____ mm (typical 0.15–1.5mm depending on tray)

-

Width: ____ mm; Roll OD: ____; Core: ____

-

Finish: gloss / matte / anti-fog

-

Printing: none / sushi print / premium look / other: ____

-

Sealing: lidding film type ____; target seal window ____

-

Shelf-life target: ____ days; packaging type: normal / MAP / VSP: ____

FAQ

Q1: Is laminated PET/PE food-safe?

Many suppliers position PET/PE laminates as food-grade and suitable for meat trays and ready-to-eat packs; confirm compliance documents for your destination market.

Q2: What makes laminated PET/PE easier to seal than some mono sheets?

The PE layer provides heat-sealing properties and moisture resistance, while PET maintains clarity and stiffness—often improving real-world sealing stability.

Q3: Should I choose PET/PE or PET/CPP / PP/CPP?

PET/PE is a solid baseline for sealing-friendly thermoforming. If you need stronger barrier/easy-peel repeatability/print durability or cold-chain toughness, PET/CPP or PP/CPP may be a better engineered choice.