(1) Define the Seal Window

Set the sealing range where peel stays smooth and hermetic integrity is maintained. Typical starting points:

· PET-based lidding: 110–130 °C (flat-jaw), pressure 0.2–0.4 MPa, dwell 0.4–0.8 s

· PP-compatible: 120–140 °C, adjust dwell slightly higher

Record the lowest temp that seals hermetically (Tmin) and the highest that still peels cleanly (Tmax). Your seal window = Tmin~Tmax.

(2) Choose Target Tear Force

Expressed as N/15 mm. Practical bands:

· Dairy/RTD: 4–6 N/15 mm (gentle, consumer friendly)

· Snacks/Bakery: 6–9 N/15 mm (balance integrity/peel)

· Industrial/food service: 8–12 N/15 mm (robust seal)

Measure with a tensile tester; test after aging (24–48 h) and across storage temps.

(3) Control the Variables

· Tray rim flatness & film tension (avoid micro-channels)

· Surface energy/treatment level for print/lamination

· Jaw type (flat vs serrated) & coating cleanliness

· Environment: oil, condensing moisture, or powder contamination

(4) Validate on Line

Run a short matrix trial: temps × dwell times × pressures. Capture peel curves and failure modes (adhesive/cohesive).

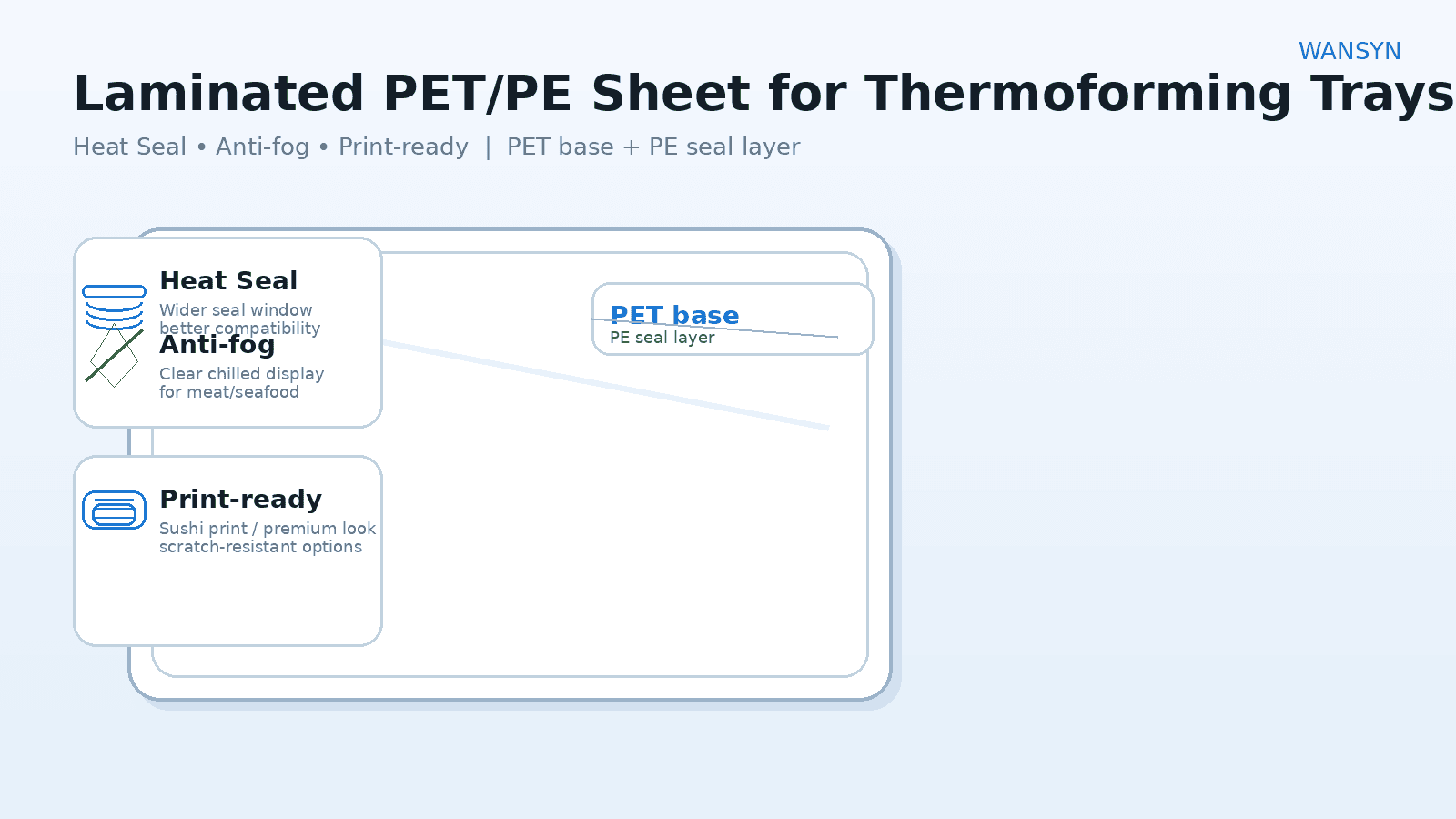

(5) When to Use Add-Ons

· Anti-fog for chilled displays

· Tamper evidence (patterned peel)

· Print-ready primers for brand work