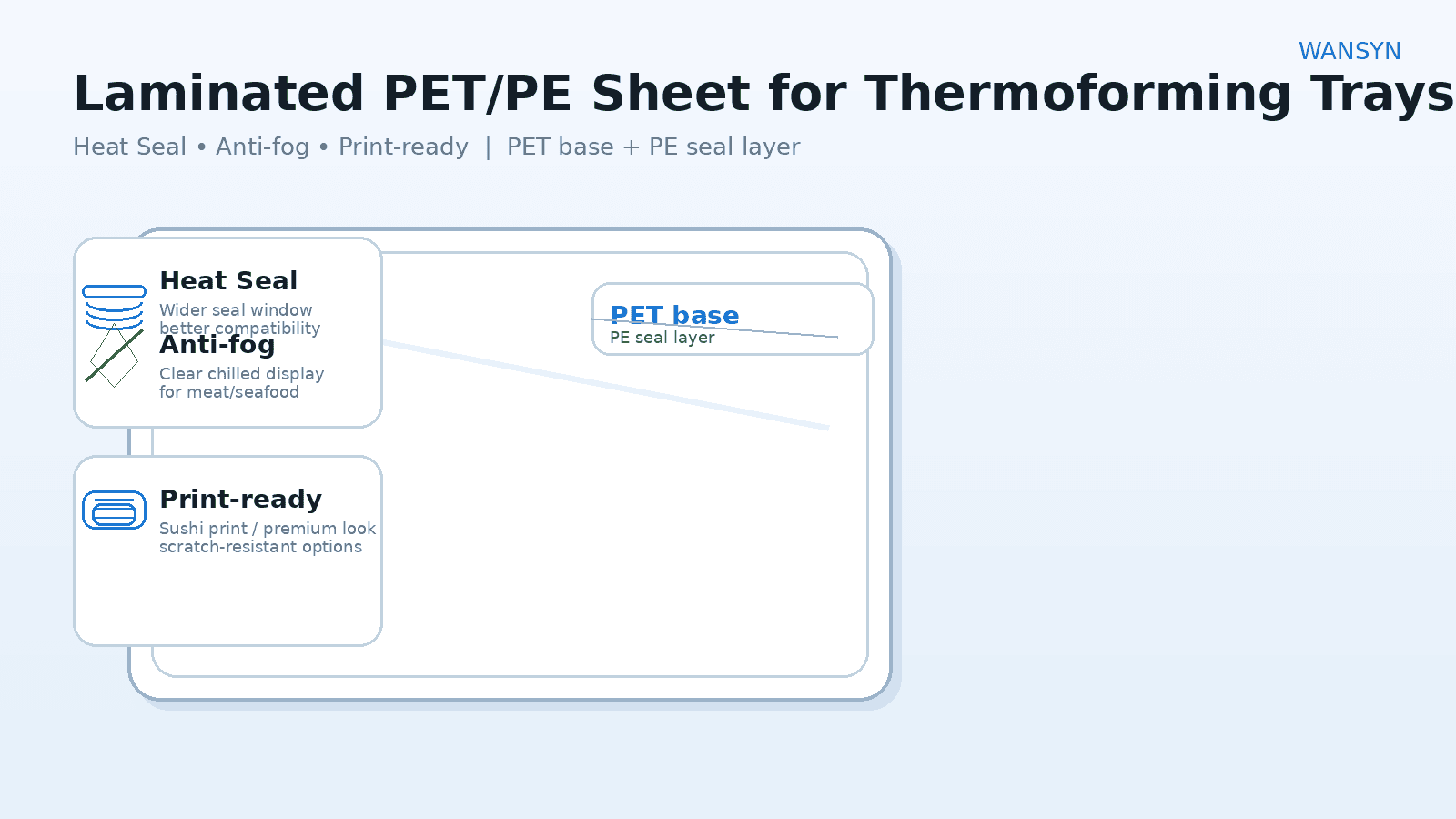

PET — Clarity & Barrier Workhorse

· Pros: high clarity/low haze; good stiffness; barrier upgrades (mPET/AL-PET); excellent brand display

· Use: chilled foods, dairy, bakery, premium display, skin-pack bases

· Notes: pair with easy-peel if consumer opening is key; manage crystallization on line

PP — Seal-Layer Flexibility & Cost Control

· Pros: good heat resistance; compatible with PP or PE seal layers; cost-effective for flow-pack; chemical resistance

· Use: snack lines, lidding with peel control, hot-fill or microwavable concepts

· Notes: transparency lower than PET; tune anti-fog/print primers as needed

PS — Display & Rigidity for Sushi/Confectionery

· Pros: appealing gloss; easy forming; good rigidity; ideal for sushi trays and chilled display

· Use: deli/retail trays, confectionery inserts

· Notes: watch low-temp brittleness—specify anti-condensation and low-temp formulas

Quick Selector

· Premium display & barrier → PET (upgrade to mPET/AL-PET if needed)

· Peel control & flow-pack → PP

· Sushi/deli trays with high gloss → PS